Unique hotel furniture customization helps a hotel create a distinct brand identity. This bespoke approach significantly enhances guest experience. Hotels that implement custom-designed furniture solutions observe a 27% increase in guest satisfaction ratings compared to establishments using standard furnishings. This applies to all hotel room furniture. Such tailored designs offer a strategic advantage. Many wonder, “What is the process of customizing hotel furniture?” Finding a skilled hotel furniture manufacturer is essential. It is also important to know, “How to evaluate a reliable hotel furniture manufacturer in China?” for a successful project.

Key Takeaways

- Custom hotel furniture helps hotels create a unique brand. It makes guests happier. Hotels see a 27% rise in guest satisfaction with custom furniture.

- The customization process starts with clear goals and a budget. Designers create plans. They choose strong materials like hardwood and metal. These choices make furniture last longer.

- Manufacturers make a sample piece first. This sample is checked carefully. This step ensures the furniture meets all quality needs before making many pieces.

- Good packaging protects furniture during shipping. Skilled teams assemble and place furniture. A final check makes sure everything is perfect for guests.

- Hotels must understand furniture warranties. They follow cleaning guides. Repair services help furniture last. This care keeps the hotel looking good for a long time.

Initial Consultation and Design for Hotel Furniture Customization

The journey to perfect hotel furniture customization begins with a thorough initial consultation. This crucial phase lays the groundwork for the entire project, ensuring everyone shares the same vision.

Defining Project Scope and Vision

Every successful project starts with a clear understanding of its goals. Hotels need to define their project scope and vision from the outset. This means clearly outlining what they want to achieve with the new furniture. They consider the hotel’s brand identity, its target guests, and the overall aesthetic they wish to create. For example, a boutique hotel might aim for a chic, modern look, while a resort might prefer a more relaxed, tropical feel. Understanding these elements helps the design team create furniture that truly reflects the hotel’s unique character and enhances the guest experience. This initial clarity prevents misunderstandings later and guides all subsequent design choices.

Budgeting and Timeline Planning

Establishing a realistic budget and timeline is essential for any hotel furniture customization project. Hotels must allocate funds wisely across different furniture categories. Typically, essential furniture like beds and seating takes up a significant portion of the budget.

| Essential Furniture Category | Budget Allocation (%) |

|---|---|

| Overall Essential Furniture | 50%–65% |

| Beds and Mattresses | 25%–35% |

| Seating Arrangements | 15%–20% |

| Storage Solutions | 10%–15% |

| Desk and Workstation Areas | 5%–10% |

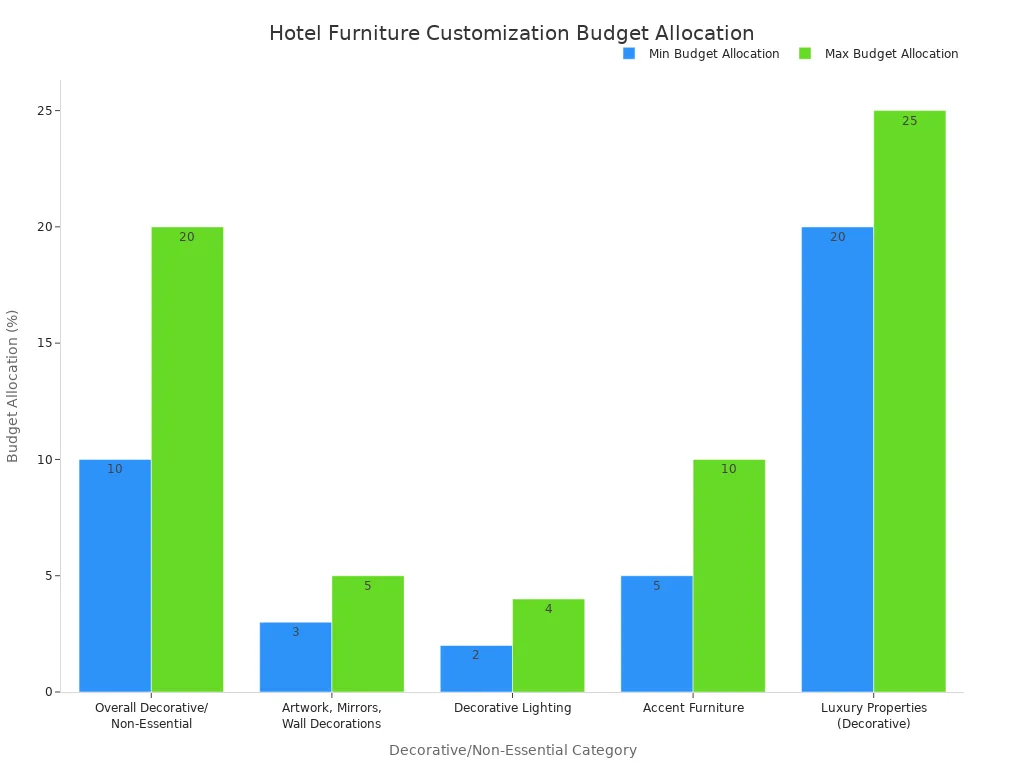

Decorative and non-essential items also play a vital role in setting the mood and style.

| Decorative/Non-Essential Category | Budget Allocation (%) |

|---|---|

| Overall Decorative/Non-Essential | 10%–20% |

| Artwork, Mirrors, Wall Decorations | 3%–5% |

| Decorative Lighting | 2%–4% |

| Accent Furniture | 5%–10% |

| Luxury Properties (Decorative) | 20%–25% |

Here is a visual breakdown of budget allocation for decorative and non-essential categories:

When considering the overall cost, custom hotel furniture typically accounts for 20%–40% of the total FF&E (Furniture, Fixtures, and Equipment) budget. This percentage varies based on the project’s specific scope, such as whether it focuses on guestrooms, public areas, or food and beverage spaces. Hotels also need to understand how manufacturers break down costs.

| Component | Typical Allocation (%) |

|---|---|

| Materials | 30%–45% |

| Direct Labor | 20%–30% |

| Finishing/QA | 5%–10% |

| Packaging & Logistics | 5%–15% |

| Design & Engineering | 5%–10% |

| Factory Overhead | 8%–15% |

| Profit Margin | 8%–20% |

Alongside budgeting, setting a clear timeline is equally important. This includes key milestones for design approval, prototyping, production, and installation. A well-planned timeline helps keep the project on track and ensures timely delivery.

Conceptual Design and Space Planning

Once the vision and budget are clear, the design team moves into conceptual design and space planning. This is where initial ideas start to take shape. Designers create mood boards, which are collections of images, colors, and textures that convey the desired aesthetic. They also produce sketches and 3D renderings. These visuals help hotels visualize how the custom furniture will look and feel in their spaces.

Space planning is another critical aspect. Designers carefully consider the layout of each room to optimize functionality and flow. They determine the best placement for each furniture piece, ensuring it fits well and allows guests to move comfortably. This planning maximizes the use of space and creates an inviting atmosphere. The goal is to create designs that are not only beautiful but also practical and durable for the hotel environment.

Material and Finish Selection

Choosing the right materials and finishes is a critical step in hotel furniture customization. These choices directly impact the furniture’s look, feel, durability, and how much care it needs. Hotels must select materials that match their design vision and can withstand daily use.

Solid hardwood is often the top choice for hotel furniture because it lasts a very long time. It naturally resists daily wear and tear. With good care, hardwood furniture can last for many decades. Oak, for example, offers great strength. Teak has natural oils that resist moisture, making it good for humid places. Mahogany is famous for its rich colors. Mango Wood provides a sustainable option with its own unique look.

Metal frames and accents also add great strength to furniture. Aluminum is light but strong. Steel offers amazing strength for its weight, perfect for parts that hold a lot of weight. These metals are very durable and do not need much upkeep. This makes them ideal for busy hotel areas.

Marble often appears on tabletops, console surfaces, and as decorative inlays. Its natural weight and strength offer both practical use and beauty. Marble is a long-lasting choice for hotel furniture. Glass and acrylic materials are also strong and easy to clean. They work well in high-use areas of hotels. Designers often use them for sleek tabletops and decorative shelves.

Different materials have different lifespans and maintenance needs. Understanding these helps hotels make smart choices.

| Material | Lifespan | Maintenance |

|---|---|---|

| Hardwood | 15-20+ years | Moderate |

| Engineered Wood | 7-15 years | Low-Moderate |

| Metal | 20+ years | Low |

| Upholstered Items | 5-10 years | High |

| Stone/Marble | Lifetime | Low |

Proper daily maintenance is key to making hotel furniture last longer. Simple habits can make a big difference:

- Use microfiber cloths to dust wooden furniture, TV panels, and other surfaces every day.

- For detailed designs on hotel case goods, use soft brushes to clean small spaces.

- Wipe down high-touch areas like desks, nightstands, and remote controls with a disinfectant.

- Clean up any spills right away.

Beyond the main materials, selecting the right finishes is also important. Finishes include stains, lacquers, and upholstery fabrics. They protect the furniture and add to its overall style. A durable finish can prevent scratches and stains, keeping the furniture looking new for longer. Hotels should choose finishes that are easy to clean and maintain, ensuring their custom pieces remain beautiful and functional for years.

Prototyping and Sample Approval for Hotel Furniture Customization

After initial designs, the next crucial step involves prototyping and sample approval. This phase ensures the furniture meets all expectations before full production begins.

Creating Detailed Technical Drawings

Designers first create detailed technical drawings. These drawings are like blueprints for the furniture. They show exact measurements, materials, and construction methods. Many manufacturers now use 3D modeling software for this stage. This software offers many advantages. It allows for better collaboration among teams. Designers, engineers, and manufacturers can work on the same project at the same time. This reduces misunderstandings. The software also creates highly realistic renderings. These renderings give a true-to-life preview of the final product. This helps both designers and clients. It also offers unmatched flexibility for easy customization. You can quickly adjust dimensions, materials, and features based on client preferences. This makes the design process agile. Furthermore, 3D modeling reduces prototyping costs. Manufacturers can refine digital prototypes. This eliminates the need for many physical versions. It significantly cuts down costs and time.

Manufacturing the First Sample Piece

Once the technical drawings are complete and approved, the manufacturer creates the first sample piece. This physical sample is a critical step. It allows everyone to see and touch the actual furniture item. This piece serves as a tangible representation of the design. It helps confirm the chosen materials, finishes, and construction quality. Manufacturers pay close attention to every detail during this stage. They want to ensure the sample accurately reflects the approved drawings and design intent.

Comprehensive Sample Review and Feedback

The sample piece then undergoes a comprehensive review. This is a vital part of hotel furniture customization. The hotel’s design team and other key people carefully examine the sample. They look at several important criteria:

- They thoroughly evaluate the sample for comfort, aesthetics, and craftsmanship.

- They conduct rigorous testing for durability to ensure high standards.

- They seek feedback from the design team and key stakeholders.

- They make necessary adjustments or refinements before final production.

- They consider budgeting and cost factors to align with financial goals without compromising quality.

This detailed review helps identify any areas needing improvement. Feedback is crucial here. It ensures the final product will perfectly match the hotel’s vision and quality standards.

Iteration and Final Sample Approval

After reviewing the first sample, the team often finds areas for improvement. This leads to the iteration phase. It is a crucial step. Designers and manufacturers work together to refine the sample. They address any feedback received. This ensures the final product perfectly matches the hotel’s vision.

However, this phase can present challenges.

- Detailed Review Requirements: Teams must meticulously check many elements. These include wood species, finish colors, door/drawer styles, and hardware. They also look at countertop materials, sink specifications, and accessory placement. Each point needs careful thought. If not aligned with the client’s vision, it can lead to more iterations.

- Impact on Manufacturing Lead Time: Manufacturing does not start until all approvals are secured. This also includes the down payment. Delays in the iteration phase directly extend the overall project timeline. This creates pressure for thorough yet timely reviews.

- Multiple Decision-Makers: If several people make decisions, coordinating their reviews can cause delays. It can also lead to conflicting feedback. This prolongs the iteration phase.

- Busy Approvers: Stakeholders, especially executives, often have many other priorities. This can cause approval tasks to be delayed. They might even get deprioritized.

- Antiquated Processes: Relying on old methods, like printing physical proofs, can cause problems. Using email for approvals can lead to inefficiencies. Feedback can get lost. Requests might be overlooked.

- Multiple Approvers: Managing feedback from several reviewers is difficult. It often results in conflicting suggestions. These require extra time to resolve. They can also put the creative team in a tough spot.

Once all adjustments are made, the manufacturer creates a revised sample if needed. The team then conducts another thorough review. They check every detail. When everyone is completely satisfied, they give the final sample approval. This green light means the design is perfect. It signals the start of full-scale production. This careful process ensures the hotel receives exactly what it envisioned.

Production and Quality Control in Hotel Furniture Customization

After approving the sample, the project moves into full-scale production. This phase focuses on efficient manufacturing and strict quality control. These steps ensure every piece of furniture meets the hotel’s high standards.

Sourcing Raw Materials and Components

Sourcing raw materials and components is a critical first step in furniture production. Manufacturers carefully select materials that meet both design specifications and ethical standards. Ethical sourcing means evaluating supplier business practices. This includes how they treat workers, the environment, and local communities. It covers sustainable practices like fair wages, safe working conditions, responsible waste management, and efficient water use. This approach considers the full scope of environmental, social, and governmental (ESG) practices throughout the product’s life.

Certifications like the Forest Stewardship Council (FSC) chain of custody are very important. They help identify ethically sourced raw materials, especially for timber and rubber. FSC certification verifies that forest-based materials come from ethical sources at every step of the supply chain. This helps companies stay compliant and makes their products more visible to consumers.

Ethical sourcing offers many benefits:

- Protect environments and resource access: It prioritizes environmentally sustainable practices. This reduces carbon emissions, water use, and waste. It also preserves natural resources for communities and future generations.

- Boost consumer appeal and avoid costly legal trouble: It follows local, global, and ethical regulations. This protects businesses from lawsuits related to illegal practices like child labor or toxic waste dumping. It also appeals to consumers who will pay more for ethical goods.

- Improve social and cultural well-being: It ensures workers’ rights and well-being. It protects indigenous communities from the negative impacts of mining and manufacturing. It also supports resource preservation.

- Maintain regulatory compliance: It helps companies stay ahead of evolving international, industrial, and local regulations. This avoids legal challenges and maintains market access.

Manufacturers follow a clear process for sustainable sourcing:

- Understand What Makes a Material Sustainable: They evaluate materials based on renewability (like bamboo or cork), low environmental impact (minimal energy, water, chemicals), recyclability/biodegradability, ethical sourcing (fair labor, social responsibility), and durability.

- Build Relationships with Certified Suppliers: They connect with suppliers who have certifications like FSC, Fair Trade, or B Corp. They also join industry groups like the Sustainable Furnishings Council.

- Prioritize Local and Regional Sourcing: This reduces transportation emissions. It also allows for closer quality control and supports local artisan communities.

- Utilize Reclaimed and Upcycled Materials: They source from salvage yards or demolition sites. This reduces waste and helps create unique pieces.

- Adopt Transparent Supply Chain Tracking: They use tools like blockchain to verify material origins. They also clearly communicate where materials come from to consumers.

Manufacturing Process and Techniques

The manufacturing process involves skilled craftspeople and advanced machinery. They transform raw materials into finished furniture pieces. This stage combines traditional woodworking techniques with modern technology. For example, artisans might hand-carve intricate details. At the same time, CNC machines precisely cut wood panels. Upholstery teams carefully select and apply fabrics. They ensure a perfect fit and finish. Metalwork involves welding and finishing to create strong frames and accents. Throughout this process, manufacturers focus on efficiency and precision. They aim to minimize waste and maximize output. Each step builds upon the last, ensuring consistency and quality across all furniture items.

Implementing Strict Quality Control Checks

Implementing strict quality control checks is essential throughout the production process. This ensures every piece of custom hotel furniture meets the highest standards. Manufacturers use a multi-stage approach to quality assurance.

Here are the key stages of quality control:

- Material Inspection: Raw materials are checked for defects or inconsistencies before production begins.

- In-Process Inspection: The manufacturing process is monitored to ensure adherence to quality standards at every step.

- Final Product Inspection: A thorough examination of the finished product identifies any defects or inconsistencies before shipment.

Manufacturers also conduct specific types of inspections:

- First-Article Inspections: These happen at the beginning of production. They verify that quality meets all requirements.

- In-Process Inspections: These ensure that manufacturing processes and techniques are followed correctly.

- Pre-Shipment Inspections: These control quality and identify defects before products ship out.

- Container Loading Supervision: This ensures proper loading methods and verifies counts on-site.

- Sorting Rework: This involves deploying inspectors to factories or warehouses. They inspect production or perform rework operations.

Quality assurance teams also perform critical tests:

- In-Process Quality Monitoring: QA teams monitor aspects like joint stability and finish quality during manufacturing. For example, they use digital calipers to check dimensions. This ensures measurements are within ±0.01 mm of design specifications. This helps catch issues early.

- Final Product Assessment: Completed furniture undergoes rigorous tests. These check for safety, durability, and functionality. This ensures the furniture withstands real-world use.

- Critical Quality Assurance Tests:

- Durability Testing: This assesses how well furniture endures stress. For example, a chair must withstand 100 kg for 10,000 cycles.

- Stability Testing: This checks if furniture remains steady under weight. For instance, a table should not tip with 20 kg on one edge.

- Flammability Testing: This ensures upholstery resists ignition. For example, it must meet California TB 117-2013 standards.

- Finish and Colorfastness Testing: This verifies resistance to scratches and color retention. For example, there should be no visible fading after 40 hours of light exposure.

Adhering to Industry Standards and Certifications

Meeting industry standards and certifications is not just a good idea; it is a must for hotel furniture. These guidelines ensure the furniture is safe, durable, and performs well. Manufacturers follow strict rules to protect guests and the hotel’s reputation.

Several important organizations set these benchmarks. They include:

- NFPA standards: The National Fire Protection Association sets crucial rules for flame retardancy tests. This helps prevent fires.

- BIFMA standards: The Business and Institutional Furniture Manufacturers Association focuses on structural integrity and durability. Their standards ensure furniture can handle heavy use.

- ASTM standards: ASTM International provides benchmarks for fire resistance and structural integrity.

- ANSI: The American National Standards Institute offers comprehensive benchmarks for commercial furniture.

- ISO: The International Organization for Standardization ensures international compliance.

- California Bureau of Household Goods and Services (CBHGAS): This bureau oversees product certification to meet specific safety and quality standards.

These standards cover many critical areas. They emphasize:

- Fire Resistance: Furniture must use fire-resistant materials. It also needs to pass flame retardancy tests. This minimizes fire hazards in hotel rooms and public spaces.

- Structural Integrity and Durability: Standards like BIFMA and ASTM make sure furniture can withstand the rigorous demands of hospitality use. This means chairs do not break easily, and tables stay sturdy.

- Accessibility: Furniture design often considers accessibility for everyone, including guests with disabilities. This aligns with ADA (Americans with Disabilities Act) compliance.

- Legal Compliance: Adhering to regulations is vital. Manufacturers maintain test reports and compliance certificates. This helps hotels avoid potential legal issues.

- Sustainability: Many standards now include environmental and climate considerations. This means using eco-friendly yet safe materials.

Manufacturers take several steps to meet these high standards. They focus on:

- Material Safety: They use non-toxic, flame-retardant, durable, and long-lasting materials. This ensures guest safety and furniture longevity.

- Thorough Testing: Manufacturers conduct tests for weight capacity, stability, and durability. For example, they might test how much weight a chair can hold before it breaks.

- Building Code Compliance: They adhere to local and national guidelines for fire safety, accessibility, and sustainability.

- Ergonomic Design: Furniture should prevent injuries and strain. Designers consider factors like height and overall comfort. This makes the furniture pleasant and safe for guests to use.

- Regular Maintenance and Inspections: Hotels must perform regular maintenance and inspections. This prolongs furniture lifespan and ensures ongoing safety. It also helps check for recalls or hazards.

By following these industry standards and certifications, manufacturers deliver furniture that is not only beautiful but also safe, reliable, and built to last. This commitment to quality gives hotels peace of mind.

Logistics, Delivery, and Installation of Custom Hotel Furniture

After the manufacturing process, the journey of your custom hotel furniture continues with careful logistics, delivery, and installation. This final stage ensures your beautiful pieces arrive safely and are perfectly placed in their new home.

Packaging and Protection Strategies

Proper packaging is crucial to protect your custom furniture during its journey. Manufacturers use expert methods to prevent damage. They create customized packaging solutions that fit each product’s unique size, shape, and fragility. This means using custom-fit inserts or molded foam for odd shapes and extra padding for delicate items. They also use high-quality packing materials. Think heavy-duty boxes, bubble wrap for shock absorption, and foam inserts for a snug fit. Strong, tamper-proof sealing methods, like reinforced tape and strapping, keep packages secure. This prevents accidental openings and deters theft. For example, they might disassemble removable parts like legs or drawers and wrap them separately. They also use corner protectors on furniture corners and cover entire pieces with furniture blankets or bubble wrap.

Efficient Shipping and Transportation

Choosing the right shipping method is key for getting your furniture to its destination efficiently. For smaller batches within the country, Less-Than-Truckload (LTL) shipping is often cost-effective. However, it involves more transfers, which can increase damage risk. If you have a large volume going to one place, Full Truckload (FTL) shipping offers better control and less risk because it has fewer handoffs. For big international projects, ocean freight is the most budget-friendly option. But remember, it takes weeks for delivery. Many companies also use Third-Party Logistics (3PL) providers. These experts help manage shipping efficiently. They use their connections with carriers to get better rates and streamline the whole process.

On-Site Assembly and Placement

The final step involves assembling and placing the furniture in your hotel. This part can sometimes have its own challenges. Teams often face space limitations for assembly, especially in smaller rooms or tight corridors. Maneuverability can also be tricky in stairwells, elevators, and hallways. Sometimes, there is not enough equipment or resources for unloading all the pieces. Communication between different vendors can also be a hurdle. Plus, assembling furniture for dozens or even hundreds of rooms requires careful planning and coordination. Despite these challenges, skilled installation teams work hard to ensure every piece is correctly assembled and perfectly placed, ready for your guests.

Post-Installation Inspection and Handover

After the installation team finishes their work, a crucial step follows: the post-installation inspection. This final check ensures every piece of furniture meets your expectations and is ready for guests. It is like a final quality assurance before the grand reveal. This step confirms everything is perfect, from safety to aesthetics.

A thorough inspection involves a detailed checklist. This checklist covers many important areas.

- Safety and Compliance Checks:

- Inspect for fire safety compliance, especially for upholstered furniture. It must meet fire-retardant standards.

- Check for chemical safety. All paints, adhesives, and finishes should be non-toxic and eco-friendly.

- Perform stability tests. This prevents tipping hazards, especially for heavy case goods.

- Consider child and elderly safety. Look for rounded edges, secure railings, and reinforced structures.

- Aesthetic and Finishing Inspections:

- Confirm color and texture consistency across all production batches.

- Ensure flawless finishing. There should be no visible bubbles, scratches, or peeling.

- Examine upholstery integrity. Look for even stitching, no loose threads, or fabric defects.

- Check for seamless assembly. Components should fit perfectly, with no gaps or misalignments.

- Test for smooth functionality. Drawers, doors, and hinges should operate effortlessly.

- Product Specific Checks:

- Verify product assembly. Check for easy assembly/disassembly, proper accessories/fittings, and good alignment.

- Perform a product functional check. All functions should work to full capacity and adhere to client specifications.

- Conduct a stability test. Place furniture on a flat surface to check for wobbling.

- Do a fatigue test. This involves repeated use for 20 cycles or client specifications without breakage or deformation.

- Apply a static loading test. Load the furniture with nominal weight for a specified time without breakage or damage.

- Check color specifications. They should conform to Pantone codes.

- Measure wood moisture content. It must be within specified tolerance for wood furniture.

- Perform an odor check. There should be no offensive or unexpected odor, comparing it with the approved sample.

- Conduct a dimensional check. Physical measurements must conform to technical drawing specifications.

- Measure and record the net and gross weight.

Once the inspection is complete and all items pass, the team formally hands over the furniture. This usually involves signing off on documentation. This confirms your satisfaction with the installation. This final step ensures your custom pieces are ready to welcome guests and enhance their stay.

Aftercare and Long-Term Maintenance for Custom Hotel Furniture

After your custom hotel furniture arrives and is installed, the journey does not end. Proper aftercare and long-term maintenance are vital. These steps ensure your investment lasts for many years. They also keep your hotel looking its best. This commitment to care protects your brand image and guest satisfaction.

Understanding Warranty and Guarantees

Understanding the warranty and guarantees for your custom pieces is very important. Most manufacturers offer a warranty for their products. Typical warranty periods for custom hotel furniture are five years from the date of delivery. These warranties generally cover defects in materials and workmanship under normal use. They also include damaged parts, repair and replacement services, and freight charges. Manufacturers often provide on-site or factory service.

However, these warranties usually do not cover normal wear and tear. They also exclude damage from misuse or improper handling. Damage due to unsuitable environmental conditions or failure to perform manufacturer-recommended maintenance is not covered. Other consequential damages, warehousing/storage costs, and third-party maintenance are also typically excluded.

Providing Care and Cleaning Instructions

Proper care and cleaning keep your furniture looking new. Manufacturers provide specific instructions for each material. Always follow these guidelines carefully. Regular dusting prevents dirt buildup. Promptly cleaning spills avoids stains. Using the right cleaning products for wood, metal, or upholstery protects the finishes. This proactive approach extends the life of your furniture. It also maintains its aesthetic appeal for guests.

Offering Repair and Replacement Services

Even with the best care, furniture can sometimes need repairs. Offering repair and replacement services is a smart long-term strategy. Customized hotel furniture can save maintenance and replacement costs in the long run. This is due to its quality and durability. Repair services allow for customization and upgrading of existing pieces. This includes finishes, colors, and hardware. You can align them with evolving brand or design aesthetics without the high cost of replacement. Professional repair experts can match current trends or new branding. This offers flexibility that replacement cannot.

Repair services also enhance the durability and lifespan of furniture. They restore it to a near-new condition. This includes repairing structural damage, strengthening joints, and restoring finishes. This extends the life of furniture for several more years. It leads to long-term cost efficiency. You avoid frequent replacements, especially in high-traffic areas. This also demonstrates the hotel’s emphasis on quality and details. It shapes a good service reputation and brand image. This enhances your market position.

Ensuring Furniture Longevity and Performance

Ensuring your custom hotel furniture lasts a long time and performs well is crucial. This protects your investment. It also keeps your hotel looking elegant and functional. Hotels can reduce replacement costs by following best practices for furniture longevity. Prioritizing cleaning and protecting furniture ensures its long-term durability. This also prevents wear and tear, maintaining a polished look for guests. Utilizing professional services further extends the life of hotel furniture.

Hotels should adhere to industry standards and regulations. This includes ADA for accessibility, such as ensuring 32 inches of clear passage and specific bed heights. Fire safety standards for materials are also very important. Following Architectural Woodworking Standards (AWI) helps. It recommends Custom Grade for high-quality wood furniture and Premium Grade for high-use items. A robust warranty, ideally a 5-year industry standard, reflects product durability. Comprehensive maintenance routines are also key. These include daily cleaning like dusting, spot cleaning, and damage inspection. Deep cleaning involves caring for wooden furniture, upholstery, and metal/glass surfaces. Proactive protection measures also help. Use coasters and mats. Rotate cushions and pillows. Select scratch-resistant materials for pet-friendly rooms.

Investing in high-quality, bespoke furnishings designed for durability is a smart move. Custom pieces withstand the rigors of hospitality use. They also maintain their aesthetic appeal. High-quality furnishings lead to long-term savings. They reduce the need for frequent replacements. Exceptional quality items show less wear. They maintain appearance and functionality longer. This reduces expenses in repairs and replacements. Combining a custom approach with a commitment to quality creates durable and inviting environments for your guests.

A streamlined hotel furniture customization process offers many benefits. It enhances guest experience and improves durability. It also ensures a distinctive interior that aligns with the hotel’s brand identity. This approach creates unique furniture solutions, making hotels memorable. It also allows for tailored designs and ensures durable, aesthetically pleasing furniture through quality assurance.

A reliable manufacturing partner is crucial. They focus on quality, customization, and sustainability. They also align with your budget and have a good reputation. Look for eco-friendly practices, factory storage, and a solid warranty. Strategic investment in custom hotel furniture creates a lasting impact. It elevates a hotel’s competitive edge and guest satisfaction.

FAQ

What is the typical timeline for custom hotel furniture?

A custom furniture project usually takes 12-20 weeks. This includes design, prototyping, production, and delivery. Complex designs or large orders might extend this timeline. Early planning helps keep the project on schedule.

How do hotels ensure quality in custom furniture?

Hotels ensure quality through strict checks. They review detailed technical drawings and approve physical samples. Manufacturers conduct in-process and final inspections. They also adhere to industry standards like BIFMA and NFPA.

What are the benefits of custom hotel furniture over standard options?

Custom furniture enhances brand identity and guest experience. It offers unique designs tailored to specific spaces. This leads to better functionality and durability. It also provides a strategic advantage in the market.

How do hotels maintain custom furniture for longevity?

Hotels maintain furniture with proper care and cleaning. They follow manufacturer instructions for each material. Regular dusting and prompt spill cleanup are key. Professional repair services also extend furniture life.

What certifications should hotels look for in furniture manufacturers?

Hotels should look for certifications like FSC for sustainable wood sourcing. They also need BIFMA for durability and NFPA for fire safety. These certifications ensure quality, safety, and ethical production.