Budget predictability relies on knowing the full cost of your hotel furniture. Many expenses exist beyond the initial purchase price. A Hotel Furniture Manufacturer often quotes only the ex-factory cost. You must understand all direct and indirect expenses. This Sourcing hotel furniture from China guide helps accurately determine your total investment. A Top hotel furniture supplier in China or a Reliable Hotel Furniture Supplier, like Taisen hotel furniture factory Ningbo, values informed clients.

Key Takeaways

- The ex-factory price is only the start. Many other costs add to the total price of hotel furniture.

- You must include shipping, taxes, and customs fees in your budget. These costs can be very high.

- Quality checks and insurance protect your money. They help avoid problems with your furniture.

- Always set aside extra money for unexpected costs. This helps you stay on budget.

- A detailed spreadsheet helps track all expenses. This shows the true cost of your furniture.

Understanding the Ex-Factory Price of Hotel Furniture

When you first look at buying furniture from China, the ex-factory price is usually the starting point. This price covers the cost of making the furniture. It includes materials, labor, and the factory’s profit. However, this price does not include any costs for moving the furniture from the factory. It also does not include shipping or taxes.

What is the Unit Cost of Hotel Furniture?

The unit cost of hotel furniture is simply the price for one piece or one set of furniture. This is the ex-factory price per item. For example, a factory might quote $150 for one hotel bed frame. This $150 is the unit cost. It is the base price before any other expenses add up. Buyers need to know this number to start their budget calculations.

How Do MOQs Impact Hotel Furniture Pricing?

Minimum Order Quantities, or MOQs, significantly affect the price you pay for hotel furniture. Factories set MOQs because producing smaller batches costs them more per unit. When you order more, the per-unit price often drops. Different types of suppliers have different MOQs and pricing structures.

| Supplier Type | Average Price per Set (FOB) | MOQ |

|---|---|---|

| Large Factory | $380–$520 | 1–2 containers (≈50–100 sets) |

| Mid-Sized Manufacturer | $290–$380 | 20–50 sets |

| Trading Company | $320–$420 | 10+ sets |

Large factories offer better prices per unit due to their scale. However, trading companies often provide more flexibility. They also communicate faster. Buyers should consider both the cost and the service level. They also need to think about their order volume when making decisions.

Strategies for Negotiating Hotel Furniture Prices

Negotiating prices can save you money on your hotel furniture order. Smart buyers use several tactics to get better deals.

- Understand the quotation and costing structure: This helps you see where costs come from. It allows for effective price negotiation. It also helps optimize your budget and promotes transparency.

- Utilize efficient procurement strategies: Combining orders can make the process smoother. Working with a trusted supplier can also lead to better deals.

- Leverage bulk orders for better pricing: Ordering large amounts often secures better deals. This lowers the cost per piece.

Domestic Logistics and Port Charges for Hotel Furniture in China

After you agree on the ex-factory price, the furniture still needs to leave the factory. It must travel to a Chinese port. This journey involves several costs. These costs are part of domestic logistics and port charges. You need to include them in your total budget.

What are the Inland Transportation Costs for Hotel Furniture?

Factories in China are often not right next to a port. So, you must pay to move your furniture from the factory to the port. This is called inland transportation. Trucks usually carry the goods. The cost depends on how far the factory is from the port. It also depends on the size and weight of your order. Sometimes, the factory arranges this. Other times, your freight forwarder handles it. Always clarify who pays for this part of the journey.

What are the Export Customs Clearance Fees for Hotel Furniture?

Before your furniture can leave China, it needs export customs clearance. This means the Chinese government must approve its departure. You will pay fees for this process. These fees cover paperwork, inspections, and the services of a customs broker. A customs broker helps ensure all documents are correct. They make sure your shipment follows all export rules. These fees are a necessary step for international shipping.

What are the Port Handling Charges for Hotel Furniture in China?

Once your furniture arrives at the Chinese port, more charges apply. These are port handling charges. They cover the cost of moving your goods within the port. This includes loading the furniture onto the ship. It also includes terminal handling charges (THC). Security fees and documentation fees are also part of this. These charges ensure your hotel furniture gets safely onto the vessel for its overseas journey.

International Shipping Costs for Hotel Furniture (Ocean Freight)

After your hotel furniture leaves the Chinese port, it travels across the ocean. This journey involves significant costs. These are international shipping costs, also known as ocean freight. You must understand these charges to budget correctly.

FCL vs. LCL Pricing for Hotel Furniture Shipments

You have two main choices for ocean shipping: Full Container Load (FCL) or Less than Container Load (LCL). Each option has different pricing. LCL shipments are priced per cubic meter (CBM). This makes LCL budget-friendly for smaller shipments. FCL shipping uses a flat-rate pricing model. You pay for the entire container, no matter how much space your goods use.

The decision point for switching from LCL to FCL is usually around 13-15 cubic meters. LCL is generally cheaper below this volume. FCL becomes more economical above it. LCL incurs additional costs. These include consolidation fees, handling charges, and documentation expenses. It can also mean higher insurance premiums due to more handling. FCL has fewer extra charges. You pay for the whole container, but you avoid consolidation, deconsolidation, and potential storage fees.

| Feature | LCL Shipping | FCL Shipping |

|---|---|---|

| Freight Cost | Priced per cubic meter (CBM) or weight, cost-effective for smaller shipments. | Flat rate for the entire container. More economical for larger shipments. |

| Cost-Effectiveness Threshold | Cheaper for shipments below 13-15 CBM. | More cost-effective for shipments above 13-15 CBM. |

| Delivery Speed | Slower due to consolidation and deconsolidation processes. | Faster as the container moves directly from origin to destination. |

Understanding Fuel and Currency Surcharges for Hotel Furniture

Fuel and currency changes can add to your shipping bill. Fuel surcharges directly impact freight rates. The U.S. Department of Energy’s national average diesel fuel price determines these surcharges weekly. This ensures a standardized approach across freight carriers. Currency changes also introduce additional costs for international shipments. When you calculate freight costs for international deliveries, consider potential currency fluctuations. They can increase the total expense.

How Do Peak Season Surcharges Affect Hotel Furniture Costs?

Shipping costs can rise during certain times of the year. These are peak season surcharges. Shipping lines add these fees when demand for cargo space is high. This often happens before major holidays or during busy trade periods. For example, before Christmas or Chinese New Year, you might see these extra charges. They ensure carriers can manage the increased volume. Plan your shipments to avoid these periods if possible. This helps you save money.

Import Duties and Taxes on Hotel Furniture in the Destination Country

Once your hotel furniture arrives in your country, you face another set of costs. These are import duties and taxes. Your government collects these fees. They are a significant part of the total cost. You must understand them to avoid surprises.

What Tariffs and Customs Duties Apply to Hotel Furniture?

Tariffs and customs duties are taxes on imported goods. Your government sets these rates. They vary based on the type of product and its origin country. For hotel furniture, these duties can be a percentage of the furniture’s value. You pay these duties to your country’s customs agency. A customs broker often helps you calculate and pay these fees. They ensure your shipment clears customs smoothly.

How Does VAT or Sales Tax Affect Hotel Furniture Imports?

Value Added Tax (VAT) or sales tax also applies to imported goods. This tax is common in many countries. It adds to the total cost of your imported items. The tax usually applies to the furniture’s value plus any duties paid. For example, if your country has a 20% VAT, you pay 20% on the total declared value, including duties. This can significantly increase your final bill. Always check your local tax laws for the exact rates.

Are There Anti-Dumping Duties on Hotel Furniture?

Sometimes, governments impose anti-dumping duties. These duties protect local industries. They apply when a foreign country sells goods at a price lower than their normal value. This practice is called "dumping." If your country finds that China is dumping hotel furniture, they might add these extra duties. These duties can be very high. They aim to level the playing field for domestic manufacturers. You should research if any anti-dumping duties apply to furniture from China in your destination country.

Destination Logistics and Delivery of Hotel Furniture

Your goods have crossed the ocean. Now, they arrive in your home country. You face a new set of logistical steps and costs. These steps ensure your items reach your project site. You must account for these expenses in your budget.

What are the Import Customs Clearance Costs for Hotel Furniture?

When your shipment arrives, it must clear customs in your destination country. This process involves specific fees. You pay for the necessary paperwork and any required inspections. A customs broker often handles this complex process for you. They ensure all documents are correct and comply with local import regulations. These fees are essential to get your goods legally into the country.

What are the Port Handling Charges for Hotel Furniture at Destination?

Once your shipment reaches the destination port, the port charges fees to handle the goods. These charges cover several services. They include unloading the containers from the ship. They also cover moving your items within the port terminal. Terminal handling charges (THC) are a common part of these fees. If your goods stay at the port for too long, you might also incur storage fees. Plan for quick pickup to avoid extra costs.

What are the Inland Transportation Costs to Deliver Hotel Furniture?

After customs clearance and port handling, your goods need to travel from the port to your final destination. This is inland transportation. Trucks carry the items from the port to your hotel or warehouse. The cost for this leg of the journey depends on several factors. These include the distance from the port to your site. The size and weight of your shipment also affect the price. You might need specialized vehicles for very large or delicate items.

White-Glove vs. Curbside Delivery Costs for Hotel Furniture

After your goods clear customs, you must decide how they will arrive at your project site. Two common delivery options are curbside and white-glove service. Each option comes with different costs and levels of service. Understanding these differences helps you budget accurately.

Curbside delivery is the most basic and least expensive option. The delivery truck brings your items to the curb outside your building. The driver does not help move the items inside. You or your team must unload the truck and transport the furniture into the building. This option saves money on delivery fees. However, it requires you to arrange for labor and equipment to handle the heavy items.

White-glove delivery offers a much higher level of service. The delivery team brings the items inside your building. They often place the furniture in the correct rooms. They can also unpackage the items and assemble them. Many white-glove services also remove all the packaging debris. This service is very convenient. It saves you time and labor costs on your end. However, it costs more than curbside delivery.

Consider these typical cost differences for various items:

| Item Type | Standard Delivery | White Glove Delivery | Cost Difference (White Glove – Standard) |

|---|---|---|---|

| Bedroom Set | $150-200 | $300-400 | $150-200 |

| Treadmill | $95-125 | $225-300 | $130-175 |

| Office Furniture System | $400-500 | $650-850 | $250-350 |

| Medical Equipment | $200-300 | $600+ | $300+ |

As you can see, white-glove delivery for a bedroom set costs an additional $150-$200 compared to standard delivery. This extra cost covers the convenience and labor. For a large project, these differences add up. You must weigh the cost savings of curbside delivery against the labor and time required from your team. White-glove service can be a smart investment for complex installations. It ensures your items arrive safely and are ready for use.

Quality Control and Inspection Costs for Hotel Furniture

Ensuring the quality of your furniture from China is a critical step. It helps you avoid costly surprises later. Quality control and inspection costs are an investment. They protect your project’s budget and reputation. You need to understand these costs and their benefits.

Why are Pre-Production Inspections Important for Hotel Furniture?

Pre-production inspections happen before manufacturing begins. They are crucial for setting clear expectations. Inspectors review raw materials and initial samples. They check specifications and production plans. This early check prevents major issues down the line. It ensures the factory understands your requirements. This stage helps catch problems before they become expensive to fix.

| Critical Checkpoint | Common Defects Identified |

|---|---|

| Joint and Connection Integrity | Loose or Weak Joints, Misaligned Connections |

| Upholstery Challenges | Tears or Rips, Uneven Padding |

| Wood Quality Concerns | Warping, Knots and Voids |

| Hardware Reliability | Faulty Drawer Slides, Weak Hinges |

| Finish and Coating Defects | Cracks in Finish, Uneven Staining |

| Structural Stability | Wobbly Legs or Bases, Uneven Surfaces |

| Packaging and Delivery | Scratches or Dents, Broken Packaging |

| Fabrication Inconsistencies | Inaccurate Measurements, Misaligned Patterns |

| Odor Issues | Unpleasant Smells |

What are During Production Inspections for Hotel Furniture?

During production inspections monitor the manufacturing process. These checks happen at various stages. They ensure the factory follows quality standards. This continuous oversight helps maintain consistency. It also allows for quick corrections if problems arise.

Key quality control parameters for during-production inspections involve specific checkpoints:

- 30% QC: Focuses on raw materials, structural integrity, and internal framing.

- 60% QC: Checks assembly quality, alignment, soft-close hardware functionality, and preparation for finishing.

- 90% QC: Involves final finishing, color matching accuracy, and hardware installation.

- Pre-shipment: A comprehensive inspection including packaging checks.

Inspectors often find issues like wardrobe depth inaccuracies or LED hotspots. They also check for inadequate ventilation in minibars, drawer misalignment, incorrect socket placement, and upholstery wrinkles. First Pass Yield (FPY) is a crucial quality control parameter. It represents the percentage of products passing all quality checks on the first attempt. A realistic FPY target for custom furniture manufacturing is typically between 90% and 95%. An FPY below 90% indicates significant hidden costs from rework and wasted materials.

The Role of Pre-Shipment Inspections for Hotel Furniture

Pre-shipment inspections are the final quality check. They happen when the entire order is complete and packed. Inspectors verify the quantity, specifications, and overall quality. They also check packaging and labeling. This inspection ensures your order meets all requirements before it leaves the factory. It provides a final assurance of quality. This step minimizes the risk of receiving defective goods.

Insurance Costs for Hotel Furniture Shipments

Shipping items across oceans involves risks. Accidents can happen. Goods can get lost or damaged. Marine cargo insurance protects your investment. It gives you peace of mind during transit. You should always consider insurance when importing.

What Does Marine Cargo Insurance Cover for Hotel Furniture?

Marine cargo insurance protects your goods while they travel. This includes transit by sea, air, or land. It covers various risks. For example, it protects against physical loss or damage to your shipment. This could happen from rough seas, accidents, or improper handling during loading and unloading. It also covers theft. Imagine your carefully selected hotel furniture arriving damaged. Insurance helps cover the cost of repair or replacement. This protection is vital for international shipments.

All-Risk vs. Named Perils Coverage for Hotel Furniture

When choosing marine cargo insurance, you typically pick between two main types: All-Risk or Named Perils. Each offers different levels of protection.

All-Risk Coverage provides broad protection. It covers all causes of loss or damage. The policy covers everything unless it specifically lists an exclusion. This means if something happens, and it is not on the exclusion list, the insurance company will likely cover it. All-Risk offers the most comprehensive protection. It gives you greater security for your shipment.

Named Perils Coverage is more limited. This policy only covers losses caused by specific events. The policy lists these events. For example, it might cover fire, collision, sinking, or theft. If your goods suffer damage from something not on that list, the policy will not cover it. Named Perils coverage is usually less expensive than All-Risk. However, it leaves more gaps in protection. You must weigh the cost against the potential risks.

Tip: All-Risk coverage generally costs more. However, it offers much broader protection. Named Perils is cheaper but only covers specific, listed events. Choose the option that best fits your budget and risk tolerance.

Installation and Assembly Costs for Hotel Furniture

Your new furniture has arrived. Now, you need to put it all together and place it in the rooms. This final step also comes with costs. You must plan for installation and assembly expenses. These costs ensure your hotel rooms look perfect and are ready for guests.

What are the On-Site Labor Costs for Hotel Furniture Assembly?

Most furniture does not arrive fully assembled. Workers need to put pieces together on-site. This requires labor. The cost of this labor depends on several things. First, consider the complexity of the furniture. A simple nightstand takes less time than a large wardrobe. Second, the number of items affects the total hours. More pieces mean more work. Third, local labor rates vary. What you pay for workers in one city might be different in another. Some furniture suppliers offer assembly services. Often, you hire local contractors for this job. Always get quotes for assembly labor. This helps you budget accurately.

When is Specialized Equipment Rental Needed for Hotel Furniture Installation?

Sometimes, standard tools are not enough for installation. You might need specialized equipment. This happens when furniture pieces are very large or heavy. For example, a grand headboard or a heavy dresser might require a furniture dolly. If you need to move items to upper floors and they do not fit in the elevator, you might need a hoist. Forklifts are useful for moving many heavy boxes from the delivery truck to storage areas. Renting this equipment adds to your overall costs. Always assess your furniture’s size and weight. Then, determine if you need special tools for a smooth installation.

Contingency and Miscellaneous Costs for Hotel Furniture

Even with careful planning, unexpected costs can arise when sourcing from overseas. You should always prepare for these surprises. Accounting for contingency and miscellaneous expenses helps you stay on budget.

How Much Buffer Should You Allocate for Hotel Furniture?

You should always set aside extra money for unforeseen issues. This is your contingency fund. Experts often recommend allocating 5% to 10% of your total project cost as a buffer. This money covers things like unexpected shipping delays, minor quality issues, or sudden price changes. Having this buffer prevents you from going over budget. It gives you peace of mind.

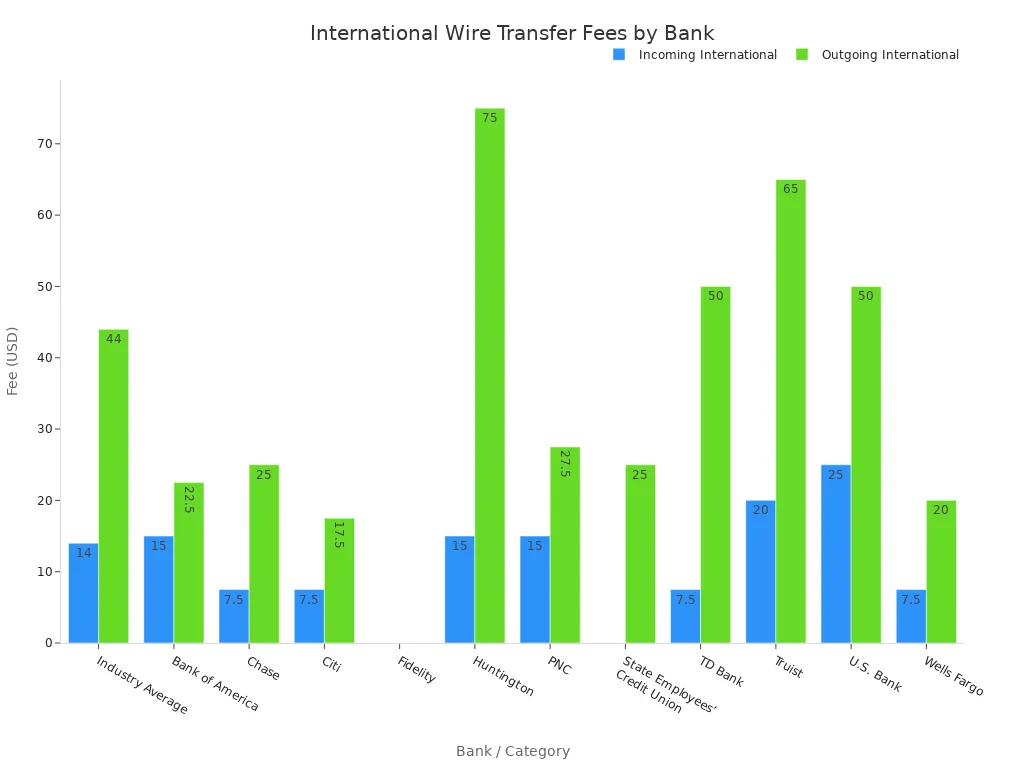

What are the Banking and Wire Transfer Fees for Hotel Furniture?

Sending money internationally involves fees. Banks charge for wire transfers. These fees can add up. For international payments, outgoing wire transfer fees average around $44. However, these fees vary greatly among banks. Some banks also charge for incoming international wire transfers. The industry average for incoming fees is $14. Sending an outbound wire transfer online can sometimes be cheaper than doing it with a bank representative. Also, some banks offer discounts for sending international wires in the local foreign currency. For example, Chase charges $40 for international wires in U.S. dollars. But it charges only $5 (or $0 for transfers of $5,000 or more) if you send it in the foreign currency.

Project Management and Communication Overhead for Hotel Furniture Sourcing

Managing an international sourcing project takes time and effort. This time translates into cost. You need to communicate with suppliers, freight forwarders, and customs brokers. This involves emails, calls, and sometimes even travel. These activities are part of project management overhead. If you hire a sourcing agent, their fees fall into this category. Even if you manage it yourself, your time has value. Do not forget to factor in these hidden costs.

Creating a Total Cost of Ownership (TCO) Spreadsheet for Hotel Furniture

You need a clear picture of all expenses when you source items from overseas. A Total Cost of Ownership (TCO) spreadsheet helps you track every dollar. This tool ensures you understand the true investment. It prevents unexpected costs from derailing your budget.

Template for Tracking All Hotel Furniture Cost Components

A good TCO spreadsheet breaks down every cost. It starts with the ex-factory price. Then, it adds all the other expenses. You can create columns for "Cost Category," "Description," "Estimated Cost," and "Actual Cost." This structure helps you compare your budget to what you actually spend. Include sections for domestic logistics, international shipping, import duties, and destination delivery. Do not forget quality control, insurance, and installation. A contingency line item is also very important. This template gives you a comprehensive view of your project’s financial health.

Example Calculation for a Typical Hotel Furniture Order

Consider a typical 100-room hotel project. The total cost for such a project can be substantial. The average cost to furnish a hotel room typically ranges from $5,000 to $15,000. This covers items like beds, lighting, decor, and accessories. For budget hotels, costs can be lower. Upscale hotels will have higher expenses. The FF&E (Furniture, Fixtures & Equipment) budget specifically for a hotel room can range from $3,000 to $10,000 per room. This depends on the hotel’s classification and material quality. This includes furniture (bed, nightstands, dressers, desks), fixtures (lighting, mirrors), and equipment (televisions, minibars).

This scenario estimates a total cost of approximately $16.5 million for a 100-room hotel, averaging $165,000 per room.

| Cost Item | Amount |

|---|---|

| Land Acquisition | $2 million |

| Site Preparation and Landscaping | $500,000 |

| Construction (Materials & Labor) | $10 million |

| Furniture, Fixtures & Equipment (FF&E) | $1.5 million |

| Technology Infrastructure | $500,000 |

| Architectural and Engineering Fees | $750,000 |

| Permits, Legal Fees, and Other Soft Costs | $750,000 |

| Pre-Opening Expenses | $500,000 |

| Total | $16.5 million |

This example shows that FF&E represents a significant portion of the overall project cost. A detailed TCO spreadsheet helps you manage this investment effectively.

A meticulous cost analysis is crucial when sourcing hotel furniture from China. This comprehensive approach ensures budget predictability. It also helps you avoid costly surprises. By understanding all expenses, you make informed procurement decisions for your investment. This detailed planning leads to successful projects.

FAQ

How can I lower my total shipping costs for hotel furniture?

Consider FCL for larger orders; it often costs less per unit. Plan shipments outside peak seasons to avoid surcharges. Consolidate orders when possible. Work with an experienced freight forwarder. They find the best rates.

What is the biggest hidden cost when importing hotel furniture from China?

Import duties and taxes often surprise buyers. These fees vary greatly by country and product type. Always research these tariffs beforehand. They add a significant amount to your total bill.

Why are quality inspections important for my hotel furniture order?

Inspections prevent costly problems. They catch defects early, before shipping. This saves money on rework or replacements. It also ensures your furniture meets your standards. Quality checks protect your investment.

Is marine cargo insurance truly necessary for hotel furniture shipments?

Yes, marine cargo insurance is very important. It protects your investment from damage or loss during transit. Accidents happen on the ocean. Insurance gives you peace of mind. It covers repair or replacement costs.

How much extra money should I budget for unexpected costs?

You should always allocate a contingency fund. Experts recommend setting aside 5% to 10% of your total project cost. This buffer covers unforeseen issues. It helps you stay within your budget.