Strategically combining materials significantly extends the lifespan of Hotel Guestroom Furniture. This approach directly addresses the challenges of frequent wear and tear in high-traffic environments. Specific material pairings can double durability. They also reduce replacement costs and ensure long-term performance for Hotel Guestroom Furniture. For instance, a Solid Wood Hotel Guestroom Furniture piece, when paired with robust finishes, offers superior longevity. When hotels consider an American Hotel Bedroom Set or a Custom King Bed Hotel Furniture item, material choice becomes paramount. Effective Hotel Furniture Procurement prioritizes these durable combinations.

Key Takeaways

- Combine solid wood with High-Pressure Laminate (HPL) for furniture that resists scratches and moisture. This makes furniture last longer in busy hotel rooms.

- Use metal frames with strong fabrics for chairs and sofas. Metal frames are very strong, and special fabrics resist stains and wear from many guests.

- Choose engineered quartz or granite for surfaces like desks and vanities. These materials do not absorb water easily and resist stains, keeping them looking good.

- Look for furniture with strong joints and good hardware, like soft-close drawers. This makes furniture more stable and prevents it from breaking down quickly.

- Consider eco-friendly materials with certifications like FSC. These materials are good for the planet and are also built to be strong and last a long time.

Understanding Durability Demands on Hotel Guestroom Furniture

High Traffic and Frequent Use in Hotel Guestroom Furniture

Hotel guestrooms experience constant activity. Guests check in and check out daily. This cycle puts immense stress on furniture. Items like beds, chairs, and desks endure repeated use. They must withstand frequent sitting, moving, and general interaction. Materials need to resist abrasion and structural fatigue. This constant demand requires furniture built for endurance. It also means materials must maintain their appearance despite continuous contact. Durability in these high-traffic areas directly impacts the furniture’s lifespan.

Cleaning Regimens and Chemical Exposure for Hotel Guestroom Furniture

Hotels maintain strict cleanliness standards. Housekeeping staff clean guestrooms thoroughly and frequently. This process involves various cleaning agents. Furniture polish helps maintain the shine and appearance of wooden elements. Multi-surface cleaners are common for items like desks, nightstands, and sofa arms. These products are often safe for wood, metal, and plastic. A multi-surface cleaner and disinfectant also cleans and sanitizes furniture surfaces. It effectively removes dirt and fingerprints. Furniture materials must resist these chemicals. They also need to withstand frequent moisture exposure without degradation or discoloration. This chemical resistance is vital for long-term aesthetic appeal and structural integrity.

Guest Behavior and Accidental Damage to Hotel Guestroom Furniture

Guests interact with furniture in many ways. Sometimes, this leads to accidental damage. Broken furniture is a frequently reported issue in hotels. Regular guest use often causes this. Insufficient repairs or failure to replace worn-out items can lead to liability for hotels if guests are injured. A scratch on the furniture is another common example of accidental damage. Materials must resist impacts and abrasions. They should also allow for easy repair or replacement of components. This minimizes downtime and replacement costs for Hotel Guestroom Furniture. Selecting robust materials helps mitigate these risks.

Core Material Combinations for Enhanced Hotel Guestroom Furniture Lifespan

Solid Wood & High-Pressure Laminate (HPL) for Hotel Guestroom Furniture

Solid wood offers timeless beauty and inherent strength. It provides a classic foundation for furniture pieces. However, solid wood surfaces can be susceptible to scratches, dents, and moisture damage in high-traffic hotel environments. Combining solid wood with High-Pressure Laminate (HPL) creates a powerful synergy. Manufacturers bond multiple layers of resin-impregnated paper under high heat and pressure to create HPL. This process results in a non-porous, impact-resistant, and scratch-resistant surface.

HPL is ideal for commercial spaces like hotels. It withstands heavy use, moisture, and wear. Architects and designers prefer HPL for its wide range of colors, textures, and finishes. This allows for creative interior applications. While HPL requires a higher initial investment, its longevity and low maintenance requirements offset this cost. This ultimately reduces replacement costs over time.

| Material | Cost Comparison (vs. TFL) |

|---|---|

| HPL (kitchen/bath) | 36% higher |

| Wood Veneer (kitchen/bath) | 79% higher |

| HPL (walk-in closet) | 21% higher |

| Wood Veneer (walk-in closet) | 55% higher |

| HPL (general assessment) | 32% less expensive than TFL |

| Wood Veneer (general assessment) | 48% less expensive than TFL |

| HPL (paired with laminates) | 21% increase |

| Wood Veneer (paired with laminates) | 50% increase |

HPL offers a high-end aesthetic at a significantly lower cost compared to solid wood or veneers. It resists stains, scratches, and heat. This makes it suitable for various furniture applications. The price advantage of laminates drives their use, especially in price-sensitive markets. This allows manufacturers to offer similar aesthetic appeal at a fraction of the cost. High-pressure laminates (HPL) are increasingly used in premium furniture. They offer superior strength and durability. They resist impact, heat, and moisture.

Engineered Wood (Plywood/MDF) & Thermofoil/Melamine for Hotel Guestroom Furniture

Engineered wood products, such as plywood and Medium-Density Fiberboard (MDF), offer excellent stability and cost-effectiveness. Plywood consists of thin wood veneers glued together in alternating grain directions. This creates a strong, warp-resistant panel. MDF uses wood fibers compressed with resin. It provides a smooth, uniform surface ideal for painting or laminating. These core materials form the structural basis for many furniture components.

Thermofoil and melamine provide durable and aesthetically pleasing finishes for engineered wood. Thermofoil involves heat-fusing a vinyl film to the substrate. This creates a seamless, non-porous surface. It resists moisture and chipping. Melamine is a resin-impregnated paper fused directly onto the engineered wood. It offers a hard, scratch-resistant, and easy-to-clean surface. Both finishes come in a vast array of colors, patterns, and textures. They can mimic natural wood grains or provide solid, contemporary looks. This combination delivers durability and design flexibility at a more accessible price point.

Metal Frames & Performance Fabrics for Hotel Guestroom Furniture

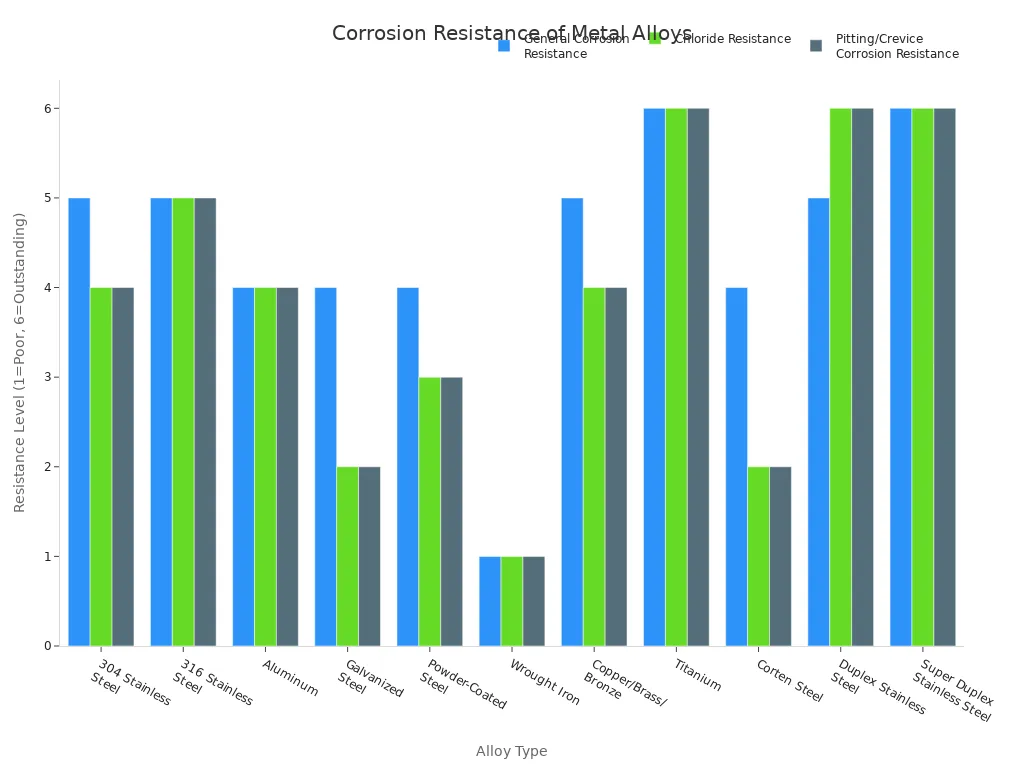

Metal frames provide exceptional structural integrity and longevity for seating and case goods. Steel and aluminum are common choices. They offer high strength-to-weight ratios. Metal frames resist warping, cracking, and insect damage. They also provide a modern aesthetic. However, metal frames require protection against corrosion. Manufacturers often use powder coating or anodizing to enhance their resistance.

Different metal alloys offer varying levels of corrosion resistance. 316 Stainless Steel, often called "marine grade," performs better than 304 Stainless Steel in saltwater and chemical exposure due to its molybdenum content. Aluminum forms a protective oxide layer. It requires anodizing or powder coating for enhanced corrosion resistance and aesthetics. Galvanized steel is cost-effective for general use. However, its zinc coating can be compromised. Powder-coated steel relies on the coating’s integrity. If scratched, the underlying steel can rust.

| Alloy Type | General Corrosion Resistance | Chloride Resistance | Pitting/Crevice Corrosion Resistance | Special Features/Limitations |

|---|---|---|---|---|

| 304 Stainless Steel | Excellent | Good (but susceptible to stress corrosion cracking in chloride environments) | Good (but susceptible to pitting in chloride environments) | Widely used, good strength and formability. Not ideal for highly corrosive marine environments. |

| 316 Stainless Steel | Excellent (superior to 304) | Very Good (due to molybdenum content) | Very Good (due to molybdenum content) | Often called "marine grade" stainless steel. Better for saltwater and chemical exposure. More expensive than 304. |

| Aluminum (various alloys, e.g., 6061, 6063) | Good (forms a protective oxide layer) | Good (but can be susceptible to galvanic corrosion when in contact with dissimilar metals) | Good (but can be susceptible to crevice corrosion in stagnant water) | Lightweight, good strength-to-weight ratio. Requires anodizing or powder coating for enhanced corrosion resistance and aesthetics. |

| Galvanized Steel | Good (zinc coating provides cathodic protection) | Fair (zinc coating can be compromised by scratches or harsh chemicals) | Fair (zinc coating can be compromised by scratches or harsh chemicals) | Cost-effective, good for general outdoor use. Not suitable for highly corrosive environments or direct saltwater exposure. |

| Powder-Coated Steel | Good (coating provides a barrier) | Varies (depends on the quality and integrity of the powder coating) | Varies (depends on the quality and integrity of the powder coating) | Wide range of colors and finishes. If the coating is scratched or chipped, the underlying steel can rust. |

| Wrought Iron | Poor (highly susceptible to rust) | Poor | Poor | Requires frequent maintenance (painting, sealing) to prevent rust. Often used for decorative purposes. |

| Copper/Brass/Bronze | Excellent (forms a protective patina) | Good (but can tarnish and corrode in certain chemical environments) | Good | Known for aesthetic appeal and antimicrobial properties. Can be expensive. Patina formation is a natural process. |

| Titanium | Outstanding | Outstanding | Outstanding | Extremely high strength-to-weight ratio, biocompatible. Very expensive, difficult to fabricate. |

| Corten Steel (Weathering Steel) | Good (forms a stable, rust-like appearance that protects the base metal) | Fair (not recommended for direct saltwater exposure) | Fair | Develops a protective rust layer. Used for architectural and artistic applications. Can stain adjacent surfaces. |

| Duplex Stainless Steel (e.g., 2205) | Excellent (superior to 316) | Excellent | Excellent | Combines properties of austenitic and ferritic stainless steels. Higher strength and corrosion resistance than 316. More expensive. |

| Super Duplex Stainless Steel (e.g., 2507) | Outstanding (superior to Duplex) | Outstanding | Outstanding | Even higher strength and corrosion resistance than duplex. Used in extreme environments like offshore oil and gas. Very expensive. |

Pairing metal frames with performance fabrics creates highly durable seating. Performance fabrics are engineered for commercial use. They resist stains, fading, and abrasion. For hotel seating, which falls under commercial environments, abrasion resistance standards for performance fabrics have evolved. While traditional classifications included ‘Heavy duty (up to 30,000 double rubs)’ for hotel rooms and ‘Extra heavy duty (over 30,000 double rubs)’ for very high traffic areas, recent trends indicate a significant increase in these requirements. Many commercial settings now specify a minimum of 50,000 double rubs. Some even require over 100,000 double rubs for enhanced durability and longevity. These fabrics maintain their appearance and integrity despite constant use and cleaning.

Stone/Quartz Surfaces & Moisture-Resistant Substrates for Hotel Guestroom Furniture

Stone and quartz surfaces offer elegance and durability. They are particularly suitable for high-contact areas. These areas include vanity tops, desk surfaces, and nightstands. These materials resist scratches, heat, and spills. However, their effectiveness depends on their inherent properties. It also depends on the substrate they rest upon.

Engineered quartz stands out for its exceptional moisture resistance. It has a water absorption rate of 0.5%. This makes it practically non-porous. Unlike many natural stones, engineered quartz countertops do not require sealing. This low absorption rate means quartz does not retain water easily. It becomes very resistant to stains and water damage. Stains occur when liquid absorbs into a material.

| Surface Type | Water Absorption Rate |

|---|---|

| Quartz Stone | 0.05–0.1% (non-porous) |

| Calacatta Quartz | 0.05–0.1% (non-porous) |

Natural stones like granite also offer excellent durability. Granite is very durable and heat-resistant. It holds up well to heavy traffic. Soapstone is another excellent choice. It has an impermeable surface, so it needs no sealing. Soapstone is also heat-resistant. It develops a distinctive patina. These properties make soapstone ideal for hotel bathroom use. It requires low maintenance and resists bacteria.

Other natural stones require more care. Travertine has a porous structure. It needs regular sealing to prevent stains. Limestone is budget-friendly. However, it is highly porous. It requires regular sealing. Limestone is susceptible to stains, scratches, and acid damage. Selecting the right stone type is crucial for long-term performance in a hotel environment.

| Stone Type | Key Properties for Hotel Use | Moisture Resistance/Maintenance |

|---|---|---|

| Travertine | Durable, luxurious appearance, soft hues. | Porous structure requires regular sealing to prevent stains. |

| Granite | Very durable, heat-resistant, holds up well to heavy traffic. | Excellent for hotel use due to strength and durability. |

| Soapstone | Impermeable surface (no sealing needed), heat-resistant, develops a distinctive patina. | Ideal for hotel bathroom use due to low maintenance and resistance to bacteria. |

| Limestone | Budget-friendly, rustic aesthetic, various soft colors. | Highly porous, requires regular sealing; susceptible to stains, scratches, and acid damage. |

Premium Hardwoods and Metal Reinforcements for Hotel Guestroom Furniture

Premium hardwoods offer unmatched beauty and inherent strength. Woods like oak, maple, and walnut provide a luxurious feel. They also offer significant durability for Hotel Guestroom Furniture. These woods resist dents and scratches better than softer alternatives. However, even the strongest hardwoods benefit from strategic reinforcement.

Metal reinforcements significantly enhance the structural integrity of hardwood furniture joints. They prevent common issues like warping, splitting, and joint loosening. Metal connectors stabilize critical connection points. These connectors include brackets, plates, screws, or gussets. They distribute mechanical stress more evenly across the joint. This reduces localized strain on wood fibers. Metal reinforcements increase load capacity. Furniture can handle heavier loads without splitting or weakening the wood. They also provide vibration resistance. This maintains stability in dynamic environments. Metal joints extend longevity. They minimize wood fatigue and prevent loosening over time. They resist shear, tension, and torsional forces more effectively than traditional wood-only joinery. This combination ensures furniture remains robust and stable for many years.

Eco-Friendly Material Combinations for Durable Hotel Guestroom Furniture

Hotels increasingly prioritize sustainability. They seek eco-friendly materials that also offer durability. Combining sustainable sourcing with robust construction methods creates long-lasting furniture. This approach reduces environmental impact and replacement costs.

Certifications guide the selection of eco-friendly materials. CertiPUR-US tests flexible polyurethane foams. It checks for durability, content, and indoor emissions in home furnishings. An independent laboratory certifies these foams. China Environmental Labelling provides environmental standards for construction materials. This includes furniture.

Other certifications focus on broader environmental impacts. LEED (Leadership in Energy and Environmental Design) is a green building certification. It sets requirements for furniture material selection and manufacturing processes. It also covers durability. This includes low formaldehyde emissions and recyclability. BREEAM (Building Research Establishment Environmental Assessment Method) is another green building certification. It has similar requirements for furniture materials as LEED. CARB P2 and E0 certifications ensure low formaldehyde emissions for engineered wood. FSC (Forest Stewardship Council) certifies boards. This indicates sustainable sourcing. Choosing materials with these certifications ensures both environmental responsibility and long-term performance.

Strategic Application of Material Combinations in Hotel Guestroom Furniture

High-Impact Zones for Hotel Guestroom Furniture

Certain areas of Hotel Guestroom Furniture endure constant stress. These high-impact zones require materials that offer superior durability and are easy to maintain. Bed frames and chair legs are prime examples. Manufacturers often choose wooden furniture for its ease of relocation, smooth edges, and straightforward repair process. Solid wood provides an economical yet upscale feel. Veneer, composed of slim wood layers, offers an elegant appearance. Laminated materials are ideal for maximum longevity and scratch resistance.

When selecting materials for hotel bed frames, several types are considered:

- Wooden Bed Frames: High-quality hardwoods like oak or walnut offer durability and warmth.

- Metal Bed Frames: Steel or iron provide strength, wear resistance, and a sleek look.

- Upholstered Bed Frames: Fabric or leather offers a luxurious feel for upscale hotels.

- HPL Bed Frames: High-Pressure Laminate resists fire, moisture, and wear, promoting long-term durability.

- Mixed-Material Bed Frames: These combine materials like wood and metal for both durability and aesthetic appeal.

The selection process involves assessing hotel needs, setting a budget, and evaluating design. Hotels prioritize quality, opting for durable materials like solid wood or HPL for longevity.

Structural Components of Hotel Guestroom Furniture

The internal framework of furniture, its structural components, must prevent sagging or breakage. These parts require specific material properties.

- Toughness: The ability to absorb energy without fracturing.

- Strength: The capacity to withstand stress without failure.

- Weight: Mass per unit volume, which influences the overall structural load.

- Hardness: Resistance to localized deformation like scratching.

- Elasticity: The ability to return to the original shape after deformation.

- Stiffness: Resistance to deformation under load, preventing excessive bending.

These properties are crucial for furniture. For example, bed slats need high stiffness to support weight without sagging. Chair frames require toughness and strength to withstand repeated use. Impact toughness is especially critical for components that experience sudden forces.

Upholstered Elements in Hotel Guestroom Furniture

Upholstered elements, like chairs and sofas, need fabrics that resist stains and clean easily. Synthetic fabrics offer excellent performance.

- Polyester: This fabric offers excellent stain resistance and color retention.

- Solution-dyed nylon: It provides exceptional durability and fade resistance for high-traffic areas.

- Olefin: This material offers superior moisture-wicking properties and remarkable colorfastness.

- Polyurethane: It resists wear, chemicals, and UV damage for ultimate durability.

- Acrylic (e.g., Sunbrella): This fabric features built-in antimicrobial properties and a luxurious feel.

Performance-enhanced natural fiber options also exist. Linen-Poly Hybrid solutions combine linen’s sophistication with polyester’s durability. Organic cotton can receive advanced eco-friendly treatments. These treatments enhance durability and functionality. They include bio-based repellents for stain resistance.

Fabrics achieve stain resistance in two main ways:

- Topical Treatments: An invisible protective finish applied to the fabric surface. This creates a barrier that repels liquids for easy blotting.

- Inherent Performance Fibers: Fibers engineered at a molecular level to be naturally stain-resistant. This protection is permanent and integral to the fiber’s structure.

Cabinetry and Drawer Boxes in Hotel Guestroom Furniture

Hotel guestroom cabinetry and drawer boxes face constant use and potential moisture exposure. Selecting the right materials for their interior construction is crucial. These materials must resist wear and maintain their appearance over time. High-Pressure Laminate (HPL) and Melamine offer excellent durability for cabinet surfaces. They resist scratches, moisture, and general wear. Plywood also provides a strong and stable core for cabinet construction.

Here is a comparison of common materials for hotel cabinetry:

| Material | Key Properties for Hotels |

|---|---|

| Plywood | Pros: Excellent strength-to-weight ratio, good screw retention, moisture-resistant (especially marine-grade). Cons: Can delaminate if exposed to excessive moisture, edges may require sealing. |

| MDF (Medium-Density Fiberboard) | Pros: Smooth surface for painting, stable, cost-effective. Cons: Not water-resistant, heavy, poor screw retention, can swell if exposed to moisture. |

| Particle Board | Pros: Most economical, lightweight. Cons: Very poor moisture resistance, low durability, poor screw retention, prone to chipping. |

| High-Pressure Laminate (HPL) | Pros: Extremely durable, scratch-resistant, moisture-resistant, wide range of finishes. Cons: Can chip at edges, difficult to repair if damaged. |

| Melamine | Pros: Cost-effective, scratch-resistant, easy to clean, moisture-resistant. Cons: Can chip, limited design options, not as durable as HPL. |

| Thermofoil | Pros: Seamless finish, moisture-resistant, easy to clean, cost-effective. Cons: Can peel or delaminate with heat exposure, difficult to repair. |

For drawer boxes, the mechanisms are just as important as the box material. Smooth operation and longevity are key. High-quality drawer slides significantly extend the lifespan of dressers and nightstands.

- Soft-close slides provide a smooth, controlled closure. This reduces noise and prevents wear from frequent use. They extend the lifespan of the drawer system.

- Ball-bearing slides and precision tracks ensure smooth movement and reduce noise. These are ideal for hospitality interiors.

- Modern furniture often includes ball-bearing drawer slides and soft-close technology. This combination offers premium performance. It defines smooth glide and mechanism lifespan.

- Durable hinges and ball-bearing slides are essential for areas with repeated daily use. They prevent failure and minimize repair costs.

These features contribute to a quiet and comfortable guest experience. They also reduce maintenance needs for hotel operators.

Beyond Materials: Design and Construction for Hotel Guestroom Furniture Longevity

Reinforced Joinery and Hardware for Hotel Guestroom Furniture

Furniture construction methods significantly impact its lifespan. Strong joinery techniques create durable pieces. Skilled artisans use mortise and tenon joints, dovetail connections, and reinforced dowels. These advanced methods prevent wobbling. They also extend the overall life of furniture in busy hotel settings. These techniques form strong bonds.

Hardware specifications are also essential for hotel furniture longevity. Drawer slide load capacity and cycle testing are crucial. A load rating shows the maximum weight a pair of slides can carry. This accounts for drawer materials and contents. Dynamic testing determines this rating. Slides are typically tested between 50,000 and 75,000 cycles for cabinet and hardware applications. One complete open/close of a drawer defines a cycle. During these tests, manufacturers check quality and durability. They measure deflection to ensure slides remain functional under a full load throughout their lifetime.

Modular and Replaceable Components in Hotel Guestroom Furniture

Modular design greatly impacts furniture repairability and lifespan. Modular modern hospitality furniture allows for component-level repair or replacement. This reduces costs. Traditional fixed furniture often requires whole-piece replacement.

| Metric | Traditional Fixed Furniture | Modular Modern Hospitality Furniture |

|---|---|---|

| Maintenance & repair | Whole-piece replacement common | Component-level repair/replacement reduces cost |

| Lifecycle cost | Potentially higher over 10+ years | Lower due to repairability and upgrades |

Modular furniture features replaceable and reconfigurable modules. This allows quick layout changes and component repairs. This component-level replacement capability extends the useful lifecycle of assets. It also reduces maintenance costs compared to traditional furniture. Modular furniture supports sustainability goals. It enables component replacement instead of whole-piece disposal. This reduces waste. Properly engineered modular furniture uses commercial-grade frames, tested joinery, and durable finishes. Its durability depends on material quality, construction, and adherence to testing standards.

Thoughtful material combinations significantly extend the lifespan of Hotel Guestroom Furniture. Investing in durable material pairings leads to substantial cost savings. It also reduces waste and ensures a consistently high-quality guest experience. Prioritizing these strategic material choices represents a long-term investment. This investment enhances both the aesthetic appeal and operational efficiency of hotel interiors. Hotels benefit from these smart decisions.

FAQ

❓ What material combination offers the best durability for hotel guestroom furniture?

Solid wood combined with High-Pressure Laminate (HPL) provides excellent durability. HPL resists scratches, impacts, and moisture. This pairing ensures long-lasting performance in high-traffic hotel environments.

🌿 How can hotels choose eco-friendly furniture that is still durable?

Hotels should look for certifications like FSC for wood and CertiPUR-US for foams. These ensure sustainable sourcing and low emissions. Combining these materials with robust construction methods creates durable, eco-friendly furniture.

💪 Which materials are best for high-impact zones like bed frames and chair legs?

Metal frames (steel, aluminum) offer superior strength and wear resistance. High-quality hardwoods like oak or walnut also provide durability. HPL bed frames resist fire, moisture, and wear effectively.

🛠️ Why are reinforced joinery and hardware important for furniture longevity?

Reinforced joinery, like mortise and tenon, prevents wobbling and extends furniture life. High-quality hardware, such as soft-close ball-bearing drawer slides, ensures smooth operation and reduces wear from frequent use.

💧 What surfaces best resist moisture and stains in guestrooms?

Engineered quartz stands out for its exceptional moisture resistance. It has a very low water absorption rate. Natural stones like granite and soapstone also offer excellent durability and stain resistance.