Asking the right questions is crucial for a successful partnership. Thorough due diligence is essential when sourcing Hotel Furniture China. This process ensures quality and reliability. It also establishes effective collaboration with a Hotel Furniture Manufacturer. Ningbo Taisen’s Hotel Cabinets offers a one-stop hotel furniture service. They aim to be a reliable hotel furniture manufacturer in China.

Key Takeaways

- Ask about a manufacturer’s experience and past projects. This shows their ability to make good hotel furniture.

- Check how manufacturers ensure quality. They should inspect materials and have clear quality checks.

- Understand their production time and shipping process. This helps you plan for your furniture delivery.

- Confirm their communication plan and support after you buy. Good communication helps the project go smoothly.

- Always check their business papers and ask for past client references. This ensures you work with a trusted company.

Assessing the Experience and Specialization of a Hotel Furniture Manufacturer

When selecting a partner for hotel furniture, clients must evaluate a manufacturer’s experience and specific expertise. This assessment helps ensure they choose a reliable and capable supplier. It also confirms the manufacturer understands the unique requirements of the hospitality sector.

What is your track record in hotel furniture manufacturing?

Clients should ask about a manufacturer’s history in the industry. A strong track record shows consistent quality and reliability. It indicates a company understands the unique demands of hotel projects. Manufacturers with many years of experience often handle complex challenges better. They have refined their processes over time. This long-standing presence in the market often means they have a deep understanding of material sourcing, production efficiency, and delivery logistics. A proven history gives clients confidence in their ability to deliver.

Can you showcase your portfolio of past hotel projects?

A manufacturer’s portfolio offers concrete proof of their capabilities. It allows clients to see the range and quality of their completed work. Many manufacturers have completed projects for various types of hotels. These include high-end hotels, resorts, and boutique accommodations. They also work on large hospitality projects. Some specialize in 3-star to 5-star hotel projects worldwide. Their portfolios often feature full-suite projects, covering guestrooms, lobbies, and meeting areas. This visual evidence helps clients make informed decisions. It demonstrates the manufacturer’s ability to meet diverse design and functional requirements.

Do you specialize in specific furniture types or materials for hotels?

Some manufacturers focus on particular furniture styles or materials. This specialization can lead to superior craftsmanship in those areas. For example, a manufacturer might excel in solid wood furniture or upholstered pieces. Others might focus on modern designs or traditional aesthetics. This focus allows them to develop deep expertise and efficient production methods for specific product lines. Understanding their specialization helps clients find a perfect match for their hotel’s design vision. It ensures the chosen Hotel Furniture Manufacturer has the right expertise for the project. This alignment leads to better quality and more suitable furniture solutions.

What are your capabilities for custom hotel furniture designs?

Many hotels seek unique furniture to match their brand identity and guest experience. Therefore, clients must ask about a manufacturer’s ability to produce custom designs. A capable Hotel Furniture Manufacturer offers extensive customization options. This includes modifying existing designs or creating entirely new pieces from client specifications. They work with various materials, finishes, and upholstery to meet specific aesthetic and functional requirements.

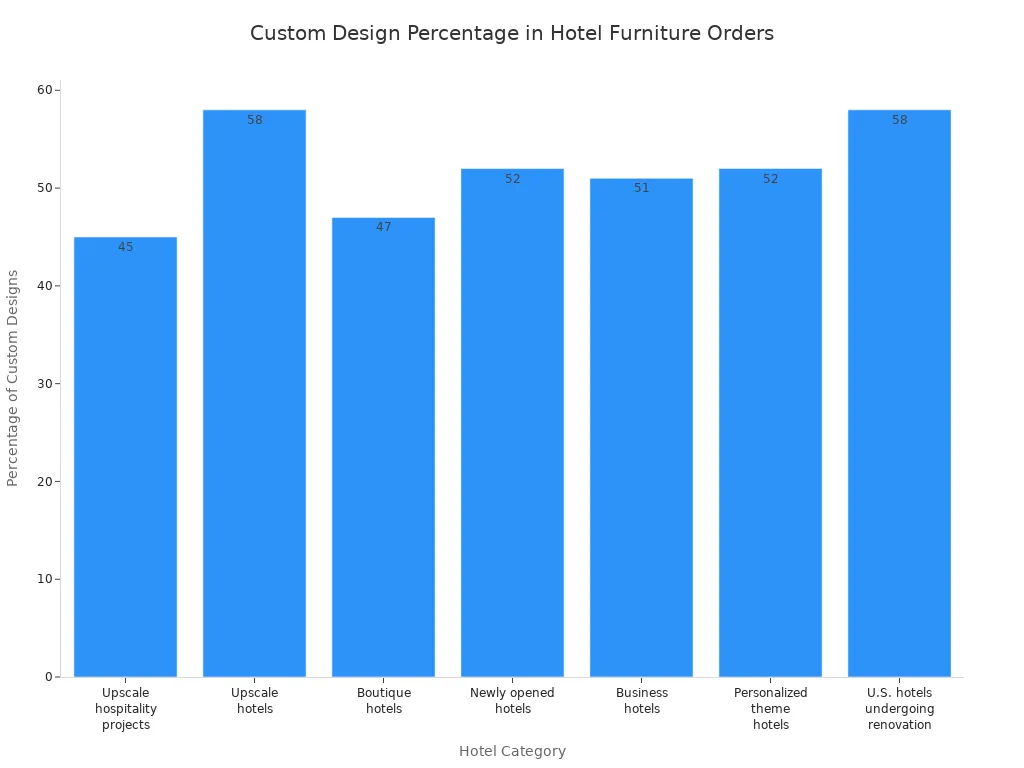

Customization is a significant trend in the hospitality industry. Many hotel projects rely heavily on bespoke furniture.

| Category | Percentage of Custom Designs |

|---|---|

| Upscale hospitality projects | Over 45% |

| Upscale hotels (preferring complete customization) | 58% |

| Boutique hotels (demand for personalized interiors) | 47% |

| Newly opened hotels (prioritizing bespoke furniture) | 52% |

| Business hotels (requesting custom desks, lighting, seating) | 51% |

| Personalized theme hotels (relying heavily on full customization) | 52% |

| U.S. hotels undergoing renovation (investing in custom furniture) | 58% |

This data shows the high demand for custom furniture across different hotel types. Upscale hotels and those undergoing renovation frequently choose complete customization.

Manufacturers with strong design teams and advanced production technology excel in this area. They transform design concepts into high-quality, functional furniture.

How do you manage design modifications during the production of hotel furniture?

Design modifications can occur during any project. Clients need to understand how a manufacturer handles these changes. A clear process for design modifications ensures efficiency and minimizes delays. Manufacturers should have a structured system for reviewing, approving, and implementing changes. This often involves detailed documentation and communication. They provide updated drawings and samples for client approval. This ensures everyone agrees on the changes before production continues. Effective management of modifications prevents costly errors and keeps the project on schedule. It also maintains the quality of the final product.

Ensuring Quality Control and Material Sourcing by the Hotel Furniture Manufacturer

Quality control and reliable material sourcing form the backbone of durable and aesthetically pleasing hotel furniture. Manufacturers must implement strict processes to guarantee product excellence. These processes ensure the furniture meets high standards for safety, longevity, and design.

What are your quality assurance protocols for hotel furniture?

A robust quality assurance system is essential for hotel furniture. It ensures every piece meets specific standards before it leaves the factory. Manufacturers implement various checks throughout the production cycle. These checks cover both safety and appearance.

- Safety & Compliance Checks: These protocols ensure the furniture is safe for guests.

- Upholstered furniture meets fire-retardant standards.

- Paints, adhesives, and finishes are non-toxic and eco-friendly.

- Stability tests prevent tipping hazards.

- Rounded edges, secure railings, and reinforced structures consider child and elderly safety.

- Aesthetic and Finishing Inspections: These inspections guarantee the furniture looks perfect.

- Color and texture consistency across production batches is verified.

- Finishing is flawless, showing no bubbles, scratches, or peeling.

- Upholstery integrity is checked for even stitching and no loose threads.

- Components fit perfectly for seamless assembly.

- Drawers, doors, and hinges function smoothly.

These detailed protocols ensure the final product is both safe and visually appealing. They reflect the commitment of a reliable Hotel Furniture Manufacturer to quality.

How do you source and verify raw materials for hotel furniture?

Sourcing high-quality raw materials is the first step in producing excellent hotel furniture. Manufacturers use careful methods to select and verify these materials. They ensure materials meet specific quality and sustainability criteria. One method used to verify raw material quality for hotel furniture is the Pre-production Inspection. This inspection occurs before manufacturing begins. It involves assessing raw materials, factory facilities, equipment, and the production line. Its purpose is to evaluate the quantity and quality of raw materials and components. This ensures they conform to product specifications. This process also helps evaluate new suppliers or existing suppliers after significant production line changes. This proactive approach prevents issues later in the production process.

What quality certifications does your Hotel Furniture Manufacturer hold?

Certifications demonstrate a manufacturer’s adherence to industry standards and best practices. They provide independent verification of quality and ethical operations. Clients should inquire about specific certifications a manufacturer holds.

- Architectural Woodwork Institute (AWI): This certification signifies a manufacturer’s ability to produce millwork according to AWI’s comprehensive industry standards. It assures clients of high-quality woodworking.

- Forest Stewardship Council (FSC): This certification indicates a commitment to sustainable practices and environmental conservation in the manufacturing process. It shows the manufacturer uses wood from responsibly managed forests.

These certifications offer peace of mind to clients. They confirm the manufacturer’s dedication to quality, safety, and environmental responsibility.

Can we conduct material inspections before hotel furniture production begins?

Clients often want to ensure the quality of materials before manufacturing starts. Conducting material inspections before production is a crucial step. This process helps guarantee that all raw materials meet the required standards. It also ensures they match the project specifications. A thorough inspection prevents potential issues later in the production cycle.

Before hotel furniture production begins, a crucial material inspection process is undertaken. This involves evaluating raw materials for quality, consistency, and adherence to specifications. For wood components, inspectors check moisture content, aiming for 6-8% to prevent issues like warping. Fabric inspections focus on fire retardancy, durability, and color consistency. Metal components are tested for structural integrity and the quality of their finish. This comprehensive inspection phase is vital for preventing defects before manufacturing starts.

Manufacturers typically have a structured approach for these inspections. This approach includes several key verification points. They use specific technical tools to ensure accuracy.

| Inspection Phase | Key Verification Points | Technical Tools Used |

|---|---|---|

| Material Inspection | Moisture content, structural properties, finish quality, regulatory compliance | Moisture meters, calibration tools, material testing equipment |

This detailed process ensures that only high-quality materials proceed to the manufacturing stage. It gives clients confidence in the final product. Clients should always ask if they can participate in or observe these critical inspections. This transparency builds trust between the client and the Hotel Furniture Manufacturer.

What is your warranty policy for hotel furniture materials and craftsmanship?

A clear warranty policy is very important. It protects the client’s investment in hotel furniture. Clients should understand what the warranty covers. They should also know how long it lasts. A good warranty typically covers defects in both materials and craftsmanship.

Manufacturers usually offer warranties for a specific period. This period can vary depending on the type of furniture and materials used. For example, a warranty might cover structural integrity for several years. It might cover upholstery for a shorter time. The policy should clearly state what constitutes a defect. It should also explain the process for making a warranty claim. This includes who to contact and what documentation is needed. A strong warranty shows a manufacturer stands behind its products. It gives clients peace of mind. They know the manufacturer will address any issues that arise after delivery and installation.

Understanding Production Capacity and Logistics from a Hotel Furniture Manufacturer

Understanding a manufacturer’s production capacity and logistical capabilities is vital. This knowledge ensures they can meet project timelines and delivery requirements. It also confirms their ability to handle the scope of your hotel furniture order efficiently.

What are your typical lead times for hotel furniture orders?

Lead times are crucial for project planning. Clients need to know when they can expect their furniture. Hotel furniture orders placed from overseas typically have a lead time of approximately 12 to 16 weeks or more for delivery. This timeframe accounts for manufacturing, quality checks, and international shipping. In contrast, American-made hotel case goods can often be designed, manufactured, and shipped within a 6-8 week timeframe. These variations depend on factors like customization, material availability, and shipping routes. Manufacturers should provide clear estimates based on the order’s complexity and volume.

What is the maximum monthly production capacity for hotel furniture?

Knowing a manufacturer’s maximum monthly production capacity helps assess their ability to fulfill large or urgent orders. This figure indicates how many pieces or projects they can realistically complete within a month. A high capacity suggests they can handle significant demand without compromising quality or delaying other projects. This information is especially important for large hotel developments or renovations requiring substantial furniture quantities. It helps clients determine if the manufacturer can scale production to meet their specific needs.

How does your Hotel Furniture Manufacturer handle large-volume orders?

Handling large-volume orders requires specialized strategies to maintain quality and efficiency. A capable Hotel Furniture Manufacturer employs several key approaches. They implement robust inspection and quality control processes. These include multi-point assessments for structural integrity, material quality, and finish consistency. Professional inspectors conduct random sampling, often checking 10-15% of bulk orders. They also use unique tracking numbers for traceability.

Manufacturers also focus on cost management and budget optimization. This involves strategic planning, multi-year procurement strategies, and detailed inventory forecasts. They leverage value engineering solutions, such as using high-quality laminates instead of solid wood, to reduce costs while maintaining quality. Bulk purchasing and modular design concepts also contribute to efficiency. Effective project management and logistics are equally important. This includes detailed procurement schedules, milestone tracking systems, and regular communication with suppliers. These strategies ensure large orders proceed smoothly from production to delivery.

What are your packaging and shipping procedures for international hotel furniture delivery?

Manufacturers must use robust packaging for international hotel furniture delivery. This protects items during long transit times and multiple handling stages. They typically employ multi-layer protection. First, they wrap individual furniture pieces in foam sheets or bubble wrap. This prevents surface scratches and minor impacts. Next, they place these wrapped items into strong corrugated cardboard cartons. For more delicate or high-value pieces, manufacturers often use custom-built wooden crates. These crates offer superior protection against crushing and severe impacts.

Manufacturers also pay close attention to internal packing. They use foam inserts or bracing to prevent furniture from shifting inside cartons or crates. This minimizes movement and potential damage. All packages receive clear labeling. These labels include product descriptions, handling instructions (e.g., "Fragile," "This Side Up"), and destination information. Proper packaging ensures the furniture arrives in perfect condition, ready for installation.

Do you have experience with international shipping and customs for hotel furniture?

Experience with international shipping and customs is crucial for a smooth delivery process. An experienced Hotel Furniture Manufacturer understands the complexities of global logistics. They regularly handle shipments to various countries. This means they are familiar with different customs regulations, import duties, and required documentation. They prepare all necessary paperwork accurately. This includes commercial invoices, packing lists, certificates of origin, and any specific declarations needed for the destination country.

Manufacturers with international experience often work with trusted freight forwarders. These partners specialize in global shipping and can navigate customs procedures efficiently. They can advise clients on Incoterms (International Commercial Terms). Incoterms define the responsibilities of buyers and sellers for the delivery of goods. This clarifies who pays for and manages the shipment at each stage. Their expertise helps avoid delays, unexpected costs, and potential issues at customs checkpoints. This ensures timely and compliant delivery of hotel furniture worldwide.

Clarifying Communication and Project Management with Your Hotel Furniture Manufacturer

Who will be our dedicated point of contact for the hotel furniture project?

Clients need a clear point of contact. This person manages all project communications. They answer questions and provide updates. This dedicated contact ensures smooth information flow. It prevents misunderstandings and delays. A single point of contact builds trust and efficiency. This individual should possess deep knowledge of the manufacturing process. They should also have the authority to address concerns promptly and effectively. This ensures clients always know who to reach for critical information.

What are your preferred communication channels for hotel furniture projects?

Effective communication is vital for any project. Manufacturers should outline their preferred channels. These channels ensure clients receive timely and relevant information. For hotel furniture projects, effective communication channels often include direct emails for formal documentation, scheduled video calls for detailed discussions, and dedicated project management platforms for tracking progress. Beyond the medium, the quality of communication matters. Manufacturers should practice clear, proactive, courteous, and transparent communication. This approach keeps clients informed and confident throughout the production process. It fosters a collaborative environment.

How frequently will we receive updates on our hotel furniture order?

Regular updates keep clients informed about their order’s progress. Hospitality furniture is a dynamic asset. It necessitates regular updates to align with evolving design trends and functional requirements. Therefore, clients need frequent updates on their orders. This ensures the furniture remains relevant and meets expectations upon delivery. A reliable Hotel Furniture Manufacturer provides a clear schedule for these updates. This might include weekly reports, milestone notifications, or immediate alerts for any significant changes. Consistent communication helps manage expectations and addresses potential issues early, ensuring the project stays on track.

How does your Hotel Furniture Manufacturer address unforeseen production challenges?

Unforeseen challenges can arise during furniture production. A reliable Hotel Furniture Manufacturer has clear strategies to manage these issues. They proactively address potential problems like budget overruns. High-quality or imported materials can sometimes exceed initial budget limits. Solutions include early planning and negotiating bulk discounts. Manufacturers also explore local suppliers when appropriate.

Supply chain and shipping delays represent another common challenge. Global supply chain issues can cause significant delivery delays. Manufacturers mitigate this by ordering materials in advance. They work with reliable suppliers and maintain backup vendors. Compliance and safety regulations are also crucial. Meeting fire safety, environmental laws, and durability standards is essential. Manufacturers ensure items hold necessary certifications like LEED or SASO. Quality control issues can also occur. Items might arrive damaged or not match specifications. Manufacturers conduct on-site inspections. They also establish detailed vendor agreements for replacements. This proactive approach minimizes disruptions and ensures project success.

What is your process for incorporating client feedback on hotel furniture?

Client feedback is vital for successful hotel furniture projects. Manufacturers have a structured process for incorporating this input. After approving the initial design concept, they create a detailed 3D model rendering. This rendering visualizes finishes, furniture, and accessories. It ensures the client clearly understands the final product. This step allows for early adjustments.

Following the 3D rendering, manufacturers often create a physical model room. They might set this up on-site or off-site. This model room tests the design in a real space. The designer, brand, and ownership teams review the setup. They make necessary changes to specifications or space plans. This happens before mass production begins. Alternatively, manufacturers send samples or set up mock-up rooms. These demonstrate design effects in a real environment. Clients confirm the plan after reviewing these mock-ups. Any necessary adjustments are made before full-scale manufacturing. This iterative process ensures the final furniture perfectly meets client expectations.

Navigating Financials and After-Sales Support from a Hotel Furniture Manufacturer

Understanding financial arrangements and after-sales support is crucial. These aspects ensure a smooth transaction and long-term satisfaction with hotel furniture purchases. Clients must clarify these details early in the partnership.

What are your payment terms and deposit requirements for hotel furniture?

Clients must understand a manufacturer’s payment terms. This prevents financial surprises. Manufacturers often have different policies for various customer types. For instance, credit account customers typically pay the full invoiced amount within 30 days of the invoice date. Customers without an approved credit account must pay for goods on a cash-with-order basis. Payments are often accepted via BACS, which is preferred, or by cheque. Cheque payments usually require a suitable clearing period, often 7-10 days. For exported goods qualifying for zero VAT rated supply, the company takes a deposit. This deposit protects against potential VAT liability. Clients pay this deposit in advance. The manufacturer fully refunds it upon meeting HMRC criteria and providing proof of export within three months, as per HMRC rules.

Do you offer volume discounts for large hotel furniture orders?

Many Hotel Furniture Manufacturer companies offer volume discounts. This incentivizes larger purchases. Clients should inquire about these potential savings. Manufacturers often structure discounts based on order quantity or total value. They might have tiered pricing models. For example, a higher discount applies to orders exceeding a certain number of units or a specific monetary threshold. Negotiating these discounts can significantly reduce overall project costs. It makes large-scale hotel furniture procurement more economical.

What is your policy on returns or addressing defects in hotel furniture?

A clear policy on returns and defects protects the client’s investment. Clients should understand the process for reporting issues. Manufacturers typically have a warranty covering material defects and craftsmanship. This policy outlines what constitutes a defect. It also specifies the timeframe for reporting problems. Clients usually need to provide photographic evidence or detailed descriptions of the issue. The manufacturer then assesses the claim. They might offer repair, replacement, or a refund, depending on the defect’s nature and severity. A transparent policy ensures fair resolution for any post-delivery concerns.

Do you provide installation guidance or support for hotel furniture?

Proper installation ensures the longevity and aesthetic appeal of hotel furniture. Clients should ask about the installation guidance and support a manufacturer offers. A reliable manufacturer provides comprehensive assistance. They offer customized consultations and project planning services. This includes guidance on design integration. They also provide training and education services for property management staff. This training covers maintaining installed furniture and equipment.

Manufacturers assist with installations involving specialty wall coverings or treatments. They address signage and wayfinding requirements. Support for installations requiring adherence to specific cultural or religious design considerations is also available. They collaborate on energy efficiency and sustainable energy solutions. Assistance with installations involving specialty textiles or fabrics is part of their service. Manufacturers offer expertise in technology integration for conference rooms or high-tech environments. They provide guidance on installations requiring specialized considerations for sustainable water management. Finally, they prioritize seismic safety and structural requirements through collaboration with structural engineers. This extensive support ensures a smooth and correct installation process.

What kind of after-sales service does your Hotel Furniture Manufacturer offer?

After-sales service is crucial for long-term satisfaction. It shows a manufacturer’s commitment beyond the initial purchase. JMHS, a hotel furniture manufacturer, explicitly offers ‘After Sales Support’. This service extends beyond the initial transaction. It provides assistance throughout the project. This support continues even after its completion.

Clients should inquire about specific after-sales services. These services often include:

- Quality & Care information

- Warranty information

This information helps clients maintain their furniture properly. It also clarifies what to do if issues arise. Comprehensive after-sales support builds trust. It ensures the furniture remains a valuable asset for the hotel.

Verifying Business Legitimacy and References of the Hotel Furniture Manufacturer

Clients must verify a manufacturer’s business legitimacy and check references. This step ensures they partner with a reputable and reliable company. It also confirms the manufacturer operates legally and delivers on its promises.

Can you provide business registration and licensing documents?

Clients should always request business registration and licensing documents. These documents confirm a company’s legal existence and operational authority. A legitimate manufacturer readily provides these records. They include the business license, which shows the company’s official name, registration number, and scope of business. Clients might also ask for tax registration certificates. These prove the company complies with local tax laws. For international trade, an export license is crucial. It permits the manufacturer to ship goods across borders.

Reviewing these documents helps clients avoid fraudulent businesses. It also ensures the manufacturer operates within legal frameworks. Clients should check the validity dates on all licenses. They should also cross-reference the information with official government databases if possible. This due diligence protects the client’s investment and ensures a smooth transaction.

Do you have client references we can contact regarding hotel furniture projects?

Client references offer invaluable insights into a manufacturer’s performance. They provide direct feedback from past customers. Clients should ask for references from projects similar to their own. This includes projects with a similar scope, budget, or hotel type. A reputable manufacturer will gladly provide a list of satisfied clients.

When contacting references, clients should prepare specific questions. They can ask about the manufacturer’s communication effectiveness. They can also inquire about product quality and adherence to delivery schedules. It is important to understand how the manufacturer handled any challenges or issues that arose. References can confirm the manufacturer’s reliability, professionalism, and commitment to customer satisfaction. This direct feedback helps clients make an informed decision.

What is the history and ownership structure of your Hotel Furniture Manufacturer?

Understanding a manufacturer’s history and ownership structure provides insight into its stability and long-term vision. A company with a long history often demonstrates resilience and experience in the industry. Clients can ask about the company’s founding date and its growth trajectory. This information helps assess its market position and operational maturity.

The ownership structure also reveals important details. A privately owned company might have different decision-making processes than a publicly traded one. Family-owned businesses often prioritize long-term relationships and craftsmanship. Knowing the ownership helps clients understand who is ultimately accountable for the company’s operations and commitments. It also indicates the company’s financial stability and its ability to sustain future projects. This knowledge builds confidence in the chosen Hotel Furniture Manufacturer.

Are you able to provide factory audit reports for your hotel furniture operations?

Clients often request factory audit reports. These reports offer transparency into a manufacturer’s operations. They confirm a factory meets specific standards. Audits cover various aspects. These include quality management systems, social compliance, and environmental practices. A reputable manufacturer readily provides these documents. They demonstrate a commitment to best practices.

Factory audits are independent assessments. Third-party auditors visit the manufacturing facility. They evaluate processes, conditions, and documentation. For example, a quality audit checks production lines, equipment maintenance, and final product inspection procedures. A social compliance audit verifies fair labor practices. It ensures worker safety and ethical treatment. Environmental audits assess waste management, energy consumption, and pollution control.

Clients benefit greatly from reviewing these reports. They gain assurance about product quality and ethical sourcing. Audit reports help mitigate risks. They confirm the manufacturer operates legally and responsibly. Clients should look for recent reports. They should also check for any corrective actions taken. This shows the manufacturer addresses identified issues. A manufacturer who provides these reports builds trust. It proves their dedication to accountability and high standards.

How does your Hotel Furniture Manufacturer ensure ethical labor practices?

Ensuring ethical labor practices is a critical concern for many clients. It reflects a company’s commitment to social responsibility. A responsible Hotel Furniture Manufacturer implements strict policies. They guarantee fair treatment for all workers. These practices protect human rights. They also uphold the manufacturer’s reputation.

Manufacturers ensure ethical labor through several key actions:

- No Child or Forced Labor: They strictly prohibit the employment of children. They also forbid any form of forced labor. This includes bonded labor or involuntary prison labor.

- Fair Wages and Benefits: Workers receive wages that meet or exceed legal minimums. They also get benefits required by law. These include social insurance and paid leave.

- Safe Working Conditions: The factory maintains a safe and healthy work environment. This includes proper ventilation, safety equipment, and emergency procedures. Regular safety training is also provided.

- Reasonable Working Hours: Employees work within legal limits for hours. Overtime is voluntary and compensated fairly.

- Non-Discrimination: The manufacturer practices non-discrimination. They do not discriminate based on race, gender, religion, or any other protected characteristic.

- Freedom of Association: Workers have the right to form or join unions. They can also bargain collectively without fear of reprisal.

Manufacturers often conduct internal audits. They also use third-party social compliance audits. These audits verify adherence to ethical standards. They provide transparency to clients. This commitment ensures products are made under humane and just conditions.

Comprehensive questioning is indispensable for a successful partnership. This blog highlighted key areas. Clients must investigate a Hotel Furniture Manufacturer’s experience, quality control, and production capacity. They also need to clarify communication, financials, and legitimacy. Choosing the right partner brings long-term benefits. These include high-quality products, efficient project execution, and lasting satisfaction for hotel furniture needs.

FAQ

How long does it take to get hotel furniture from China?

Hotel furniture orders from China typically take 12 to 16 weeks for delivery. This timeframe includes manufacturing, quality checks, and international shipping. Custom designs or large volumes may extend the lead time.

How do Chinese manufacturers guarantee furniture quality?

Manufacturers use strict quality assurance protocols. They conduct material inspections before production. They also perform safety and aesthetic checks throughout the manufacturing process. Certifications like FSC further ensure quality and sustainability.

Can hotels order custom-designed furniture?

Yes, many Chinese manufacturers offer extensive customization. They can modify existing designs or create new pieces based on client specifications. This allows hotels to match their unique brand identity and design vision.

What is the process for shipping furniture internationally?

Manufacturers use robust packaging for international delivery. This includes foam, bubble wrap, and strong cartons or wooden crates. They also handle customs documentation and work with freight forwarders to ensure smooth, compliant delivery worldwide.

What are the typical payment terms for hotel furniture orders?

Payment terms often vary. Many manufacturers require a deposit upfront. The remaining balance is due upon completion or before shipment. Some offer credit terms for established clients. Clients should clarify these terms early.