Yes, we can definitively identify the top 10 custom hotel furniture makers for 2025. This selection comes from a rigorous evaluation. It focuses on their specialization in bespoke design and quality craftsmanship. We also assess their proven project execution for the hospitality sector. A leading Hotel Furniture Supplier China might feature in this list. The criteria ensure we highlight only the best in Custom Hotel Furniture. An Affordable Hotel Project Furniture Manufacturer also earns consideration for their value. This rigorous process considers all aspects, including the quality found in offerings like Taisen’s hotel furniture, ensuring comprehensive coverage for any hotel project furniture need.

Key Takeaways

- Top hotel furniture makers offer special designs and good quality. They understand what hotels need.

- Look for companies that can customize furniture. They should use strong materials and have good designs.

- Good manufacturers manage projects well. They deliver on time and have strong customer reviews.

- Check if a company cares about the environment. They should also offer good support after you buy the furniture.

- To choose the right maker, know your project’s needs and budget. Make sure their style matches your hotel.

The Top 10 Custom Hotel Furniture Manufacturers for Your Hotel Project Furniture in 2025

Identifying the top custom hotel furniture manufacturers for 2025 involves looking at companies that consistently deliver excellence. These manufacturers combine innovative design with robust construction. They understand the unique demands of the hospitality industry. Here, we highlight some of the best in the business, known for their quality, customization, and reliability.

Oppeinhome: Comprehensive Custom Solutions

Oppeinhome has established itself as a major player, offering comprehensive custom solutions for various spaces. They specialize in kitchens, wardrobes, and hotel furniture. This company is well-known for its exceptional customization capabilities. Hoteliers can easily align designs with their specific brand aesthetics. Oppeinhome provides a complete package for any hotel project furniture need, ensuring every piece fits perfectly. Their approach helps clients achieve a cohesive and stylish look throughout their properties.

Artone Furniture: Bespoke Design and Craftsmanship

Artone Furniture earns its spot through a strong commitment to bespoke design and superior craftsmanship. They create unique pieces that truly reflect a hotel’s individual character. Artone’s team works closely with designers and owners, translating visions into tangible, high-quality furnishings. Their artisans pay close attention to every detail, from material selection to the final finish. This dedication ensures each item is not just furniture, but a work of art built to last.

Montalbano: Luxury Custom Furnishings

Montalbano represents the pinnacle of luxury custom furnishings. This manufacturer caters to high-end hotels and resorts that demand elegance and sophistication. They use premium materials and employ advanced manufacturing techniques to produce exquisite pieces. Montalbano’s designs often feature intricate details and timeless styles, elevating the guest experience. Their ability to deliver opulent and durable furniture makes them a top choice for luxury hospitality projects.

Charter Furniture: High-Volume Custom Projects

Charter Furniture excels at handling large-scale custom projects. They consistently deliver quality furnishings for major hotel chains and resorts. This manufacturer understands the demands of high-volume orders. They combine efficient production processes with a commitment to design integrity. Hoteliers trust Charter Furniture to equip entire properties with custom pieces. Their experience ensures smooth execution from concept to installation, even for the most ambitious hotel project furniture needs.

Northland Furniture: Durable and Custom-Built

Northland Furniture stands out for its durable and custom-built pieces. They craft furniture designed to withstand the rigors of daily hotel use. Northland Furniture states that all of its hotel furniture lines are manufactured to meet and exceed high durability standards. They build casegoods with components made from solid and engineered wood. They consider every detail to ensure high quality and durability. This construction will withstand the test of time.

Northland Furniture uses quality woods and craftsmanship for extra durable casegoods. They design these pieces specifically for the contract market. They also offer an industry-leading 10-year warranty. This warranty stands behind the strength and durability of their casegoods.

Northland Furniture utilizes components made from solid and engineered wood. They fortify these materials with environmentally friendly resins. Reinforcement elements are incorporated to prevent sagging or damage from heavy objects. They also use water-based stains and pre-catalyzed lacquers. This provides a more durable finish compared to traditional lacquers. Their focus on robust construction makes them a reliable choice for any hotel seeking long-lasting custom furnishings.

National Hospitality: Extensive Custom Capabilities

National Hospitality offers extensive custom capabilities. They provide a wide range of options for hotels of all sizes and styles. This manufacturer works closely with clients to bring unique visions to life. They handle everything from guest room casegoods to public area seating. National Hospitality’s team guides customers through the design and material selection process. They ensure the final products perfectly match the hotel’s aesthetic and functional requirements. Their comprehensive approach makes them a versatile partner for diverse hospitality projects.

Beaufurn: Innovative Hospitality Designs

Beaufurn brings innovative designs to hospitality furniture. They focus on creating pieces that are both stylish and functional. Beaufurn understands the need for fresh looks in hotels and restaurants. They help hotels stand out with unique and appealing pieces. For example, they incorporate a mid-century modern design with curved, clean lines in their Nova Table. This table is for indoor use in modern and minimalist restaurant settings. This design choice adds sophistication to hospitality furniture.

Bernhardt: Premium Custom Hotel Furniture

Bernhardt is a name synonymous with premium custom hotel furniture. They have a long history of crafting high-quality pieces. Bernhardt focuses on luxury and elegance. They work with top designers to create bespoke furnishings. These pieces meet the exact specifications of upscale hotels. Their craftsmanship ensures durability and a refined aesthetic. Hotels choose Bernhardt when they want furniture that makes a statement.

Kimball Hospitality: Integrated Project Solutions

Kimball Hospitality offers integrated project solutions. They manage the entire furniture process for hotels. This includes design, manufacturing, and installation. Kimball Hospitality helps clients from start to finish. They ensure every piece fits the overall vision. Their expertise makes complex hotel project furniture needs simple. They deliver consistent quality and efficient project management. This makes them a reliable partner for large-scale developments. They handle all aspects of your hotel project furniture.

CenSO Home: Global Custom Manufacturing Expertise

CenSO Home truly stands out with its global custom manufacturing expertise. This prominent hospitality furniture manufacturer boasts extensive international project experience. They have successfully completed projects spanning Europe, the Middle East, and Southeast Asia. CenSO Home’s manufacturing base is strategically located in China. You know, China is actually recognized as the leading global hub for hotel furniture production. Why is that? Well, it’s because China offers an extensive supply chain, competitive pricing, and advanced engineering capabilities. It also has a massive capacity for large-scale, fully customized projects. This means CenSO Home can deliver high-quality, bespoke furniture solutions efficiently. They meet the diverse needs of hotels worldwide. Their global reach and robust production capabilities make them a reliable partner for any hotel project furniture requirement. They ensure hotels get exactly what they envision, no matter where they are located.

Key Criteria for Identifying Top Custom Hotel Furniture Makers

Choosing the right custom furniture maker for a hotel project requires careful consideration. Several key criteria help identify the best partners. These factors ensure the furniture meets both aesthetic and functional demands.

Customization Capabilities and Flexibility

Top manufacturers offer extensive customization options. They understand that each hotel has a unique identity. Furniture choices often depend on the room structure. For example, wide rooms might use freestanding units. Small rooms benefit from space-maximizing fittings. The furniture’s design must also look attractive. It should complement the hotel’s style, whether modern or vintage. This visual appeal influences guest booking decisions. Comfort is also a priority. Makers select appropriate sizes and dimensions. They arrange furniture to avoid a cramped feeling. This provides relief to guests. Good manufacturers also consider the hotel’s brand identity. They use quality materials and work with professional designers. They personalize pieces with logos, colors, and patterns. This creates a cohesive, branded look. They also focus on durability and space optimization. They tailor furniture for tight spaces. They incorporate features like foldable designs or integrated storage. Accessibility is another important factor. Furniture should meet needs like wheelchair-friendly table heights.

Quality of Materials and Construction Standards

High-quality materials and construction are essential for hotel furniture. It must withstand constant use. Industry benchmarks define different grades. Economy grade represents minimum requirements. It is generally not suitable for hospitality. Custom grade is common for most high-quality wooden hotel furniture. It offers designers flexibility. Premium grade is for high-use and high-profile items. It signifies the highest quality. A 5-year warranty is an industry standard for guestroom casegoods. This is a critical component of a hospitality design project. Manufacturers use kiln-dried hardwood for frames. This offers strength and resists warping. High-density foam provides optimal support for cushions. It maintains shape longer. They prioritize durability in material selection. This includes reinforced joints and sturdy frames. Commercial-grade fabrics resist stains and wear. Hardwoods like oak and maple are strong. Stainless steel and aluminum are popular for metal pieces. They resist rust. Rigorous testing for strength and stability is vital. This ensures furniture meets industry standards.

Design Expertise and Innovation in Hotel Project Furniture

Leading manufacturers show strong design expertise. They also embrace innovation. Smart furniture features are now expected. These include built-in charging ports and touch controls. Biophilic designs incorporate natural materials. Wood, stone, and leather connect indoor spaces with nature. Multifunctional pieces serve many purposes. They support both productivity and relaxation. Sustainable materials are also a focus. Makers use eco-friendly options. Retro influences and tailored eclecticism create unique environments. Modern metal finishes are popular. Silver, chrome, and steel are common for hardware. Sustainability meets style in these designs. They use recycled wood and eco-fabrics. Smart furniture integrates USB ports and adjustable lighting. Minimalist aesthetics feature clean lines and neutral tones. Local craftsmanship combines global standards with cultural inspiration. Multi-functional guest rooms cater to both relaxation and productivity. This includes dining chairs that double as workspaces.

Project Management Efficiency and Lead Times

Efficient project management ensures timely delivery. Top manufacturers excel at keeping projects on schedule. They understand that delays impact hotel opening dates and revenue. Custom furniture orders often have specific lead times. A typical custom hospitality furniture order usually takes 8-10 weeks from drawing approval to delivery. This timeframe includes 3-4 weeks for component material lead times and the actual product manufacturing. Some companies, like Bandpass, might have a lead time of approximately 24 weeks once they place the order. For standard custom orders, Creative Style Furniture delivers in 12–16 weeks. Keekea handles bulk orders in about 6 weeks (40 days). Manufacturers with strong project management provide clear timelines. They communicate progress effectively. This transparency helps hotels plan their installations without unexpected delays.

Client References and Portfolio Strength

A strong portfolio shows a manufacturer’s capabilities. It includes client testimonials and case studies. These demonstrate on-time delivery and high-quality products. They also highlight the ability to handle unique and complex projects across various markets. The portfolio showcases expertise in custom hospitality furniture solutions. It shows how they transform visionary concepts into tangible realities. Manufacturers present a broad range of custom solutions, from seating to casegoods. They integrate specific themes and requirements into designs. A strong portfolio also reflects a commitment to sustainability. This includes using domestically sourced materials and environmentally responsible manufacturing practices. Reliable service and close collaboration from concept through installation are also key. A showcase of crafted projects demonstrates innovation, style, aesthetic allure, and practical functionality across diverse hotel types.

Production Capacity and Financial Stability

A manufacturer’s production capacity and financial stability matter greatly. They ensure the company can complete large projects. They also guarantee long-term support. Key financial indicators include revenue and its growth rate. These show market position and expansion capabilities. Profitability metrics, such as net profit margin, reflect operational efficiency. Liquidity ratios, like the current ratio, evaluate short-term financial stability. Leverage ratios, such as debt-to-equity, reveal reliance on debt financing. Cash flow indicators, like free cash flow, highlight liquidity strength for operations. For instance, some companies show significant online revenue. Guangzhou Wenjiasheng Network Technology Co., Ltd. has over $3,700,000 in online revenue. Shenzhen Saien Gel Product Co., Ltd. has over $1,100,000. These figures indicate strong market activity and financial health.

Commitment to Sustainability and Ethical Practices

Top furniture makers show a strong commitment to sustainability. They also follow ethical practices. This means they care about the environment and their workers. Many manufacturers use materials from responsibly managed forests. They often obtain FSC’s chain-of-custody certification. This certification proves their commitment to sustainable sourcing. It verifies their processes for producing and trading FSC-certified products. This allows them to use the globally recognized FSC label. This label shows support for responsible forestry.

Manufacturers also pursue other important certifications. These certifications demonstrate their dedication to environmentally friendly processes and healthy products. Some key certifications include:

- FEMB Level: This sets standards for environmentally friendly manufacturing.

- BIFMA Level: This promotes sustainable environments in furniture.

- LEED (Leadership in Energy and Environmental Design): This addresses sustainability in construction and design.

- SCS Global Services: This partners with companies to develop green policies.

- Greenguard and Greenguard Gold: These certify products with low chemical emissions. Greenguard Gold ensures products are safe for sensitive groups.

- MAS Certified Green: This involves emissions testing to reduce volatile organic compounds (VOCs).

These certifications assure hotels that their furniture choices support a healthier planet. They also ensure a safer indoor environment for guests and staff.

Comprehensive After-Sales Support and Warranties

Excellent after-sales support and strong warranties are crucial. They give hotels peace of mind. Top manufacturers stand behind their products. They offer clear warranty details. These warranties cover defects in materials and workmanship. A good warranty protects a hotel’s investment. It ensures furniture lasts for many years.

Manufacturers also provide comprehensive support after the sale. This includes help with maintenance and repairs. They offer guidance on cleaning and care. This helps extend the life of the furniture. Quick and efficient support minimizes downtime. It keeps hotel operations running smoothly. This commitment to long-term service builds trust. It also strengthens the partnership between the hotel and the manufacturer.

How to Choose the Right Custom Manufacturer for Your Hotel Project Furniture

Selecting the perfect custom furniture manufacturer for your hotel project is a big decision. It requires careful thought and planning. You want a partner who understands your vision and can deliver quality results.

Defining Project Scope and Budget Clearly

Before you even start looking, clearly define your project’s scope and budget. This step is crucial. Many challenges arise when these are not clear. For example, budget overruns often happen with high-quality or imported furniture. Global supply chain issues can also cause delays for custom items. These delays impact your timeline.

Developers sometimes assume guest room interiors only need simple finishes. However, guest rooms often require custom ceilings, built-in closets, and unique lighting. These elements are not usually part of a basic package. Late involvement from hotel brands can also force big changes. This leads to extra fees or schedule impacts. Evolving designs for public spaces and strict brand standards can also cause delays. Long lead times for specialty materials and custom furniture also demand early planning. Defining everything upfront helps avoid these problems.

Evaluating Specific Customization Requirements

Next, evaluate your specific customization needs. What unique features does your hotel require? Do you need furniture that fits unusual room layouts? Think about the materials, finishes, and functionalities. A good manufacturer offers flexibility. They should accommodate unique measurements and modifications. They also provide a range of styles, colors, and finishes. This ensures the furniture aligns with your hotel’s identity and functional needs.

Assessing Design Compatibility and Aesthetic Alignment

You must also assess design compatibility and aesthetic alignment. The manufacturer’s style should match your hotel’s brand. You can do this by thoroughly vetting vendors. Ask for case studies, portfolios, and client references. Review their past experience with brand guidelines.

It is also important to review manufacturer submittals with your brand’s design team. Do this before placing orders. This prevents any misalignment. Understand the design intent behind your brand standards. This helps ensure proposed alternatives maintain brand integrity. Evaluate the supplier’s expertise and their ability to handle complex custom designs. This ensures they can bring your vision to life.

Reviewing Production Capabilities and Quality Control

Hotels must thoroughly review a manufacturer’s production capabilities. This ensures they can handle the project’s scale. Look at the factory size and the machinery they use. A large, modern facility often indicates strong capacity. Ask about their production volume and how they manage large orders. Efficient manufacturers use advanced technology. They also have skilled labor.

Quality control is equally important. A reliable manufacturer has strict quality checks at every stage. They inspect raw materials. They monitor production processes. They also perform final product inspections. Ask about their quality control team and their procedures. Certifications, like ISO standards, show a commitment to quality. These checks guarantee the furniture meets high standards. They also ensure it will last in a busy hotel environment.

Verifying References and Conducting Site Visits

Always verify references. Ask the manufacturer for a list of past hotel clients. Contact these clients directly. Ask them about their experience. Inquire about product quality, delivery times, and communication. A strong track record with satisfied customers is a good sign.

Consider conducting a site visit to the manufacturer’s facility. This gives you firsthand insight. You can see their production lines. You can observe their quality control processes. A site visit helps you assess their professionalism. It also shows their commitment to craftsmanship. This step builds confidence in your chosen partner.

Understanding Contractual Terms and Warranty Details

Before signing any agreement, fully understand the contractual terms. Pay close attention to payment schedules. Clarify delivery timelines. Discuss installation responsibilities. A clear contract protects both parties. It outlines expectations and obligations.

Review the warranty details carefully. A good warranty covers defects in materials and workmanship. It specifies the duration of coverage. It also explains the claims process. A strong warranty shows the manufacturer stands behind their products. It provides peace of mind for your investment. Ensure the warranty aligns with industry standards for hotel furniture.

Prioritizing Effective Communication and Collaboration

Effective communication and strong collaboration are vital for any successful hotel furniture project. You want to ensure a smooth process from start to finish. Clear communication prevents misunderstandings. It also keeps everyone aligned with the project goals.

The hotel team must clearly articulate its vision. They should share design preferences, functional requirements, and budget constraints. This upfront clarity helps the manufacturer understand your exact needs. They can then tailor their solutions more effectively.

A good manufacturer provides regular updates. They inform you about production progress. They also highlight any potential challenges. More importantly, they offer solutions. This proactive approach helps address issues before they become major problems. They should have a dedicated project manager. This person acts as your main point of contact. This streamlines communication.

Collaboration involves working together to solve problems. Sometimes, unexpected issues arise. Perhaps a material is unavailable. Or, a design element proves difficult to manufacture. A collaborative manufacturer works with you. They find alternative materials. They suggest design modifications. This ensures the project stays on track.

“Open dialogue between the hotel and the manufacturer builds trust. It also fosters a partnership. This partnership leads to better outcomes.”

Regular meetings are also beneficial. These meetings allow both parties to discuss progress. They can review samples. They can make necessary adjustments. This continuous feedback loop ensures the final product meets your expectations. It also helps avoid costly rework. Prioritizing communication and collaboration ensures your custom furniture project delivers exceptional results. It makes the entire process more efficient and enjoyable.

Essential Considerations for Custom Hotel Project Furniture

When hotels choose custom furniture, they must think about several key factors. These considerations ensure the furniture meets all needs. They also guarantee a smooth project.

Durability and Longevity Requirements

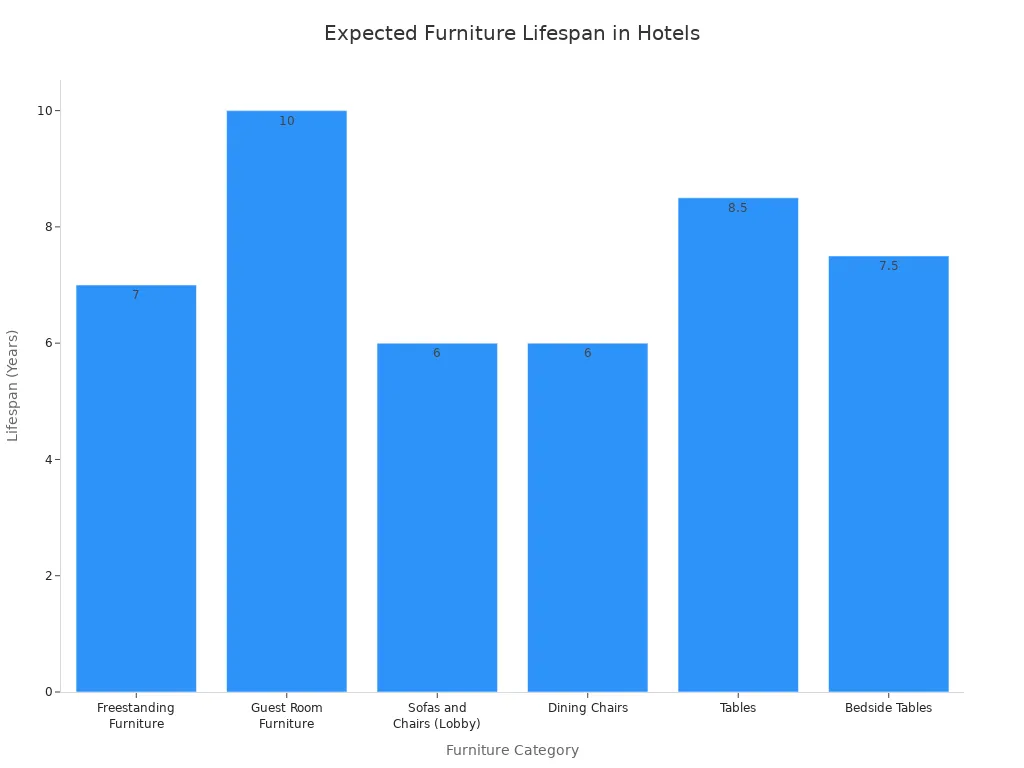

Hotel furniture faces constant use. Therefore, it needs to be very durable. Manufacturers use premium hardwoods like walnut, oak, and maple. They also use commercial-grade fabrics and high-pressure laminates. Robust metal components are essential for heavy use. Superior craftsmanship and modern manufacturing ensure structural integrity. This helps furniture withstand daily commercial demands. Metal mouldings are very durable. They outperform wood and vinyl in fire resistance and pest resistance. Stainless steel is highly recommended for its strength. Hotels often upgrade surfaces in high-traffic areas to materials like quartz. Adding metal accents to furniture corners protects them from dings. A 5-year industry standard warranty shows a manufacturer trusts their product.

Compliance with Industry Standards and Regulations

Hotel furniture must meet many industry standards. These ensure safety and quality. The National Fire Protection Association (NFPA) mandates rigorous flame retardancy tests. BIFMA standards apply to furniture like sofas and side tables. They ensure high safety. ASTM standards cover structural integrity. The American National Standards Institute (ANSI) sets benchmarks for fire resistance. Accessibility (ADA compliance) ensures furniture works for everyone. Manufacturers must use non-toxic, flame-retardant materials. They also test for weight capacity and stability. Staying updated on these rules is crucial.

Logistics and Installation Support

Efficient logistics and installation are vital for a successful project. Hotels often need warehouse storage before delivery. They also need coordinated transportation. Scheduling installation timelines carefully minimizes disruptions. Projects can face delays. The hotel site might not be ready for furniture as planned. This often means third-party storage. Planning for storage costs at the start avoids budget problems. Good communication with the installer is key. Requesting prototypes helps confirm designs. Agreeing on a clear schedule streamlines deliveries. Installers need to know the general building layout. They also need door and hallway dimensions. Planning for haul away of old furniture and cleanup of packaging is also important.

Scalability for Future Phases

Hotels often plan for growth. They might add new rooms or expand existing areas. Custom furniture manufacturers should offer scalability. This means they can easily reproduce designs. They can also adapt pieces for new spaces. A manufacturer with good scalability helps hotels maintain a consistent look. They ensure quality across all phases of development. This saves time and money in the long run. It also makes future renovations much simpler. Hotels need a partner who can grow with them.

Value Engineering Opportunities

Value engineering helps hotels get the best furniture for their budget. It focuses on maximizing value without sacrificing quality. Manufacturers offer several ways to achieve this.

-

Pre-production Site Visits: Manufacturers conduct site visits before production. This prevents wasted time, effort, and money. It ensures furniture fits and works as intended. This avoids costly rework and delays. Site visits also help project managers understand the hotel’s atmosphere. This allows manufacturers to suggest better designs and materials. They ensure longevity and a good aesthetic fit. Detailed measurements from these visits ensure furniture physically fits. This prevents returns. A completed site visit also makes delivery and installation smoother. Crews know where items go. This prevents delays and blocked utilities.

-

Strategic Investment: Hotels can focus their budget on high-traffic areas. Lobbies and dining spaces get more funding. These areas guests see most often. Hotels can choose less costly options for other spaces.

-

Long-Term Durability: Investing in high-quality, durable furniture minimizes expensive replacements and repairs. Hotels should select materials that are easy to clean. These materials require less upkeep. This saves money over time.

-

Cost-Effective Material Selection: Materials greatly impact design and cost. Hotels can explore budget-friendly alternatives. Different fabric options, for example, can save a lot of money. Many manufacturers offer various contract-grade fabrics. These provide significant savings compared to expensive brands.

-

Phased Project Rollouts: Hotels can break down large projects. They can roll them out in phases. They focus on key areas first. Then, they move to others. This might involve soft goods before case goods. Or, they might mix new and existing pieces.

-

Flexibility in Design Choices: Hotels should keep an open mind during the process. They embrace creativity to find the best solutions. This helps them achieve their vision within budget.

Selecting the optimal custom hotel furniture manufacturer is truly paramount for a project’s success. The top manufacturers we highlighted offer unparalleled expertise and deliver high quality for bespoke hotel furnishings. They understand unique needs. A thorough evaluation, based on established criteria, ensures a successful partnership. This also guarantees exceptional results for any hotel project.

FAQ

What makes a custom hotel furniture manufacturer “top-tier”?

Top-tier manufacturers offer exceptional bespoke design, quality craftsmanship, and proven project execution. They also show strong customization capabilities, efficient project management, and a commitment to durability.

How long does custom hotel furniture usually take to produce?

A typical custom order takes 8-10 weeks from drawing approval to delivery. This includes time for material sourcing and manufacturing. Larger or more complex projects might require longer lead times.

Why is sustainability important for hotel furniture?

Sustainable practices reduce environmental impact. They also ensure healthier indoor air quality for guests and staff. Many top manufacturers use eco-friendly materials and ethical production methods.

Can I get custom furniture for a small hotel project?

Yes, many custom manufacturers cater to projects of all sizes. They offer flexible solutions. They work with you to meet your specific design and budget needs, regardless of project scale.