Many top custom furniture manufacturers in China extensively support OEM and ODM for hotel project furniture. The global hotel furniture market, including hotel guest room furniture and other indoor supporting furniture, reached approximately USD 52.84 billion in 2024. This market projects a 3.7% Compound Annual Growth Rate, reaching USD 6741.22 million by 2033. These manufacturers offer unparalleled customization, quality, and efficiency, providing excellent OEM hotel furniture solutions and delivering high-quality custom furniture for hotel projects.

Key Takeaways

- Chinese manufacturers offer great value for hotel furniture. They provide custom designs, good quality, and efficient production.

- These manufacturers have strong supply chains and advanced technology. This helps them offer competitive prices and handle large orders.

- They provide many design choices. They can create unique furniture that fits a hotel’s style and needs.

- Choosing a good partner means checking their quality control. It also means looking at their ability to customize and their communication skills.

- Many Chinese manufacturers follow green practices. They use sustainable materials and ethical production methods.

Why Choose Chinese Manufacturers for Hotel Project Furniture OEM/ODM

Comprehensive Supply Chain and Advanced Technology

Chinese manufacturers offer significant advantages for hotel projects due to their comprehensive supply chain and advanced technological integration. China’s manufacturing infrastructure provides lower raw material costs, with steel, for example, costing about one-third less than in other regions. The government also reduces capital costs, supported by high savings rates and stable banks. Furthermore, China boasts some of the lowest labor costs globally, attracting foreign investment. This robust infrastructure includes a well-developed transportation system and reliable power and water supplies, facilitating efficient operations. Major ports like Shanghai, Shenzhen, and Guangzhou are among the world’s busiest, ensuring efficient handling of large cargo volumes and connecting to extensive global shipping routes. These advanced production facilities allow for extensive customization options, meeting specific aesthetic and functional requirements for hotel projects. They also support adherence to international quality standards like ISO9001 and ISO14001, along with sustainability certifications such as FSC, ensuring high-quality and environmentally responsible products.

Cost-Effectiveness and Scalability for Hotel Projects

The cost-effectiveness and scalability offered by Chinese manufacturers are crucial for hotel projects. Strategic geographical advantages and manufacturing efficiencies contribute to competitive pricing. Proximity to abundant raw materials, especially in manufacturing hubs like Foshan, significantly lowers sourcing and transportation costs. Advanced production facilities enable efficient, large-scale manufacturing, further driving down expenses. Reduced shipping costs, facilitated by proximity to major ports, offer a significant financial incentive for international buyers. For instance, a hotel bathrobe costing $15 in the US might cost $5-$8 from a Chinese manufacturer, and hotel slippers could drop from $0.50 to $0.20. Annual volume commitments with Chinese manufacturers typically lead to 10-15% discounts, which can be negotiated upfront for multiple orders. A case study of a U.S.-based electronics brand demonstrated over 50% reduction in per-unit costs for electronics production and 35% for accessory products by transitioning to OEM/ODM sourcing in China, highlighting substantial potential savings.

Proven Expertise in Large-Scale Hotel Furniture Production

Chinese manufacturers demonstrate proven expertise in large-scale hotel furniture production, handling significant volumes with precision and efficiency. Many factories possess vast facilities, such as Dugao Hotel Furniture with 50,000㎡ and over 500 workers, or Yabo Furniture with over 100,000㎡. These manufacturers leverage automation, with some reporting up to 60% automation, to enhance production capabilities.

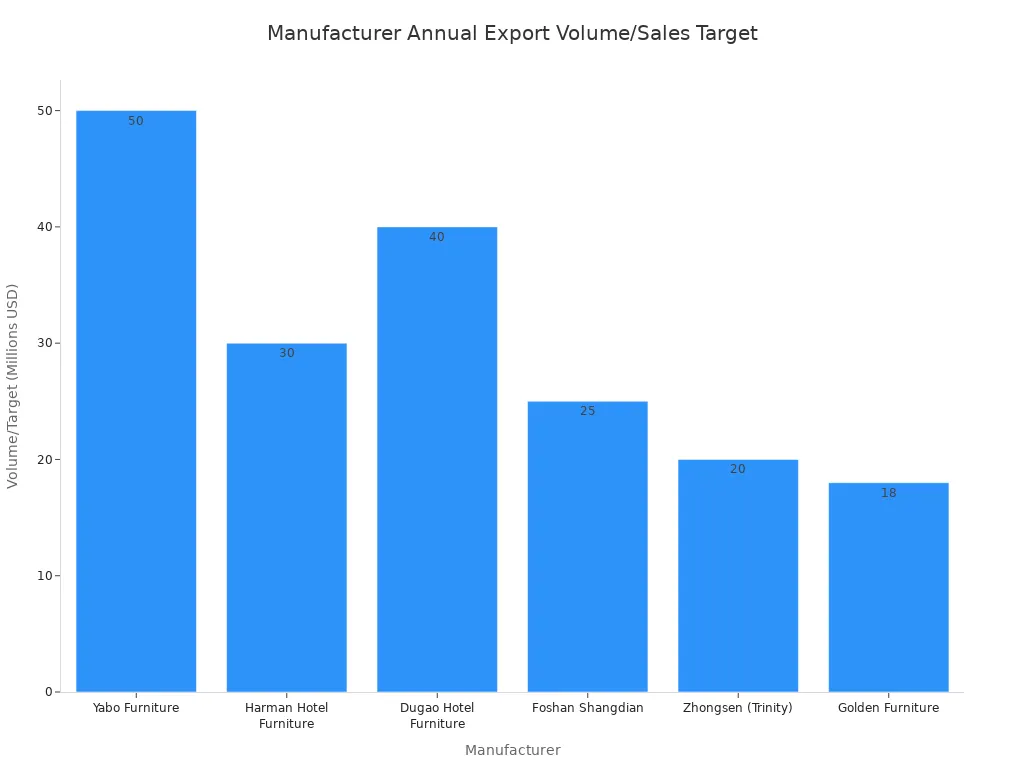

Manufacturers like Dugao Hotel Furniture achieve annual export volumes of 300M RMB (approximately $40M), while Yabo Furniture reaches around $50M. They offer integrated supply chains and one-stop solutions, from consultation to logistics and installation. Advanced manufacturing tools, including CNC cutting, 3D rendering, and CNC routers, ensure precision. Strategic locations, such as Foshan, provide direct access to raw materials and proximity to major ports, streamlining exports to over 50 countries. Companies like Golden Furniture balance large-scale production with boutique customization, and Foshan Shangdian offers low minimum order quantities (MOQs) of 5 sets, catering to diverse project sizes while maintaining capabilities for larger volumes. This extensive capacity and specialized knowledge make them ideal partners for any Hotel Project Furniture requirement.

Design Flexibility and Customization for Hotel Interiors

Chinese manufacturers offer extensive design flexibility and customization for hotel interiors. They excel at creating unique furniture pieces that enhance a hotel’s aesthetic and functionality. Manufacturers produce art furniture for public areas, prioritizing aesthetics to create rich landscape effects. They also draw inspiration from national cultural traditions, such as China’s Ming style furniture, known for its concise, straight, and powerful shape. This approach ensures designs possess longevity and appeal, moving beyond purely functional items.

These manufacturers also embrace new technologies and materials. They consider ecological factors, for example, adding negative oxygen ions to furniture fabric. They focus on optimal comfort through careful material selection and matching. Furthermore, they provide smart furniture solutions, including built-in charging stations and integrated lighting controls. They also offer smart beds for convenience and a high-tech guest experience.

Manufacturers develop modular and multifunctional designs. These pieces are easily rearrangeable and adaptable for various uses, maximizing space and functionality within hotel rooms and common areas. They create bold and artistic designs that make a statement and complement unique brand identities, often drawing inspiration from art and nature. For personalized guest experiences, they offer furniture that adapts to individual preferences, such as adjustable beds and customizable lighting. Wellness-oriented furniture, like ergonomic chairs and calming lounge areas, promotes relaxation and well-being. Finally, they deliver minimalistic yet elegant designs with sleek lines, neutral color palettes, and simple functionality, creating uncluttered, sophisticated spaces for any Hotel Project Furniture requirement.

Top Chinese Manufacturers for Hotel Project Furniture OEM/ODM

MINGSUN: Design-Driven Solutions for Hotel Projects

MINGSUN stands out as a design-oriented hotel furniture company. It skillfully integrates creativity with precise engineering. MINGSUN offers design-driven OEM/ODM solutions. The company provides comprehensive global project support. MINGSUN operates as a full-service provider. Its services include concept design, 3D modeling, sampling, production, and logistics. MINGSUN’s internal design department excels at harmonizing aesthetics and functionality. They create bespoke solutions that align with a hotel’s brand image. Their competitive edge lies in delivering immersive hospitality experiences. These experiences combine comfort, elegance, and performance. MINGSUN promises design creativity, uncompromised quality, and reliable delivery.

Key Advantage: Design-driven OEM/ODM solutions with global project support

Guangdong Richang Furniture Co., Ltd.: Luxury Hotel Furniture Expertise

RICHANG FURNITURE GROUP is a leading manufacturer. They specialize in luxury hotel furniture, villa furniture, high-end apartment furniture, yacht furniture, and wall coverings. Richang Furniture has supplied furniture for several notable luxury hotel projects.

- MGM Shanghai West Coast Hotel

- Foshan New Town Poly Intercontinental Hotel

- Guangzhou W Hotel Renovation Project

The company’s expertise ensures high-quality furnishings for prestigious hospitality environments.

Taisen Furniture: Specialized Hotel Project Furniture and OEM Capabilities

Taisen Furniture, located in Ningbo, China, specializes in dining tables and chairs, bedroom sets, and hotel furniture. They offer strong OEM capabilities for Hotel Project Furniture. Taisen Furniture has over ten years of experience in making hotel project furniture. Their production facility in Ningbo adheres to international manufacturing standards. They use advanced equipment and rigorous quality control. This ensures reliable and long-lasting products.

Taisen Furniture offers full customization for hotel cabinets. This includes choices for colors, finishes, logos, dimensions, size, material, and branding. These options align with a hotel’s identity and design theme. They use top-tier materials. These include moisture-resistant wood, corrosion-proof metals, and scratch-resistant finishes. This ensures longevity and a professional appearance in various cabinet types. Taisen provides comprehensive support services. These range from initial design consultation and quote requests to after-sales maintenance. Customers can access support via email and phone. The company offers cost-effective solutions without compromising quality. Efficient production processes ensure on-time delivery, even for large orders. Their hotel cabinets feature space-saving designs. These include built-in compartments, adjustable shelves, and slim profiles. These maximize storage in small hotel rooms, mini-bars, and vanity areas. This enhances functionality without sacrificing guest comfort.

Shangdian Hotel Furniture: Custom Solutions and Detailed Craftsmanship

Shangdian Hotel Furniture excels at providing custom solutions for diverse hotel needs. They understand each hotel possesses a unique identity. Therefore, Shangdian offers extensive customization options. These options cover materials, finishes, dimensions, and design aesthetics. The company works closely with clients. They transform design concepts into tangible, high-quality furniture pieces. Shangdian’s strength lies in its detailed craftsmanship. Skilled artisans pay close attention to every joint, surface, and curve. This meticulous approach ensures durability and a refined appearance. They combine traditional woodworking techniques with modern manufacturing processes. This blend results in furniture that is both beautiful and functional. Shangdian’s commitment to detail guarantees each piece meets stringent quality standards. This dedication makes them a reliable partner for hotels seeking bespoke furniture.

GCON Group: Leading Manufacturer for Hotel Furniture

GCON Group stands as a prominent leader among hotel furniture manufacturers in China. They have maintained a top position in the industry since 1995. This long history demonstrates their consistent quality and reliability. GCON Group specializes in custom designs for hotel furniture. They cater to the unique requirements of various hospitality establishments. The company serves major hotel chains and individual accommodations. Their reach extends to over 50 countries worldwide. This global presence highlights their capability to handle large-scale international projects. GCON Group’s expertise ensures they deliver high-quality Hotel Project Furniture solutions. They combine advanced manufacturing techniques with a deep understanding of hotel design trends. This approach allows them to create furniture that enhances guest experiences and meets operational demands.

Key Considerations for Selecting an OEM/ODM Partner for Hotel Project Furniture

Quality Control and Assurance Processes

Selecting an OEM/ODM partner requires careful evaluation of their quality control and assurance processes. A reliable manufacturer implements stringent checks at every production stage. This includes raw material inspection, in-process quality checks, and final product evaluation. Manufacturers often hold international certifications like ISO 9001, which demonstrates their commitment to quality management. They also conduct various tests to ensure durability, safety, and compliance with industry standards. Clients should inquire about the manufacturer’s quality control team, their inspection protocols, and how they handle non-conforming products. A transparent quality assurance system builds trust and guarantees the delivery of high-standard furniture.

Customization Flexibility and Design Support

An ideal OEM/ODM partner offers extensive customization flexibility and robust design support. Hotels often require unique furniture pieces that reflect their brand identity and interior design themes. The manufacturer should provide a wide range of material options, finishes, and dimensions. They must also demonstrate the capability to translate design concepts into tangible products. This includes offering services like 3D rendering, prototyping, and sample production for client approval. Strong design support ensures that the final furniture pieces align perfectly with the hotel’s aesthetic and functional requirements. This collaborative approach helps create bespoke solutions for any Hotel Project Furniture need.

Communication and Project Management Efficiency

Effective communication and efficient project management are crucial for successful OEM/ODM partnerships. Partners should establish clear communication channels from the outset. Many successful collaborations utilize email for formal communication, detailing SKUs, specifications, and packaging. WeChat serves as a primary messaging app in China for real-time daily updates, photos, and short video calls once trust develops. Project management tools like Trello or Notion help track timelines. Google Drive facilitates shared folders and product development files. Loom allows for video explanations, enhancing clarity. Translation tools such as DeepL or Google Translate can bridge language barriers, though double-checking technical terms or hiring bilingual assistants is advisable. Leveraging these technologies ensures smooth information flow and project progression.

Sustainability and Ethical Manufacturing Practices

Selecting an OEM/ODM partner also involves evaluating their commitment to sustainability and ethical manufacturing. Responsible manufacturers implement practices minimizing environmental impact. They ensure fair labor conditions. Certifications provide clear evidence of these commitments. For example, ISO 14001 demonstrates a facility’s dedication to environmental management. This includes waste, emissions, and resource use. It aligns with hotel chains’ sustainability policies or LEED/ESG goals.

Manufacturers also use timber and wood-based products from responsibly managed forests. Certifications like FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) verify this. Hotels specifying certified wood reduce reputational and supply-chain risks. They request chain-of-custody documentation, such as an FSC COC certificate, to verify materials. OEKO-TEX Standard 100 ensures textiles are free from harmful chemicals. This protects indoor air quality for upholstery fabrics and mattress covers. The Global Recycled Standard (GRS) verifies recycled content. It also confirms the integrity of the supply chain for recycled materials. This helps meet green procurement policies.

Logistics, Shipping, and After-Sales Support

Efficient logistics, reliable shipping, and comprehensive after-sales support are critical for successful hotel projects. Manufacturers must manage the entire process from production to delivery. They offer various shipping options, including sea, air, and rail freight. Understanding typical lead times helps project planning. Standard furniture typically takes 6–12 weeks for production. Custom orders require 10–16 weeks. A new furniture line, from deposit to EU warehouse via sea freight, takes 12–18 weeks. Repeat orders for established models, fabrics, and packaging usually take 8–12 weeks. For urgent projects, an aggressive timeline can be 5–8 weeks total. This includes 2–4 weeks for production, 1 week for QC and packing, and 1–3 weeks for air or rail transport.

A reliable partner provides clear communication throughout the shipping process. They offer tracking information. They also assist with customs clearance. After-sales support includes warranty provisions and maintenance guidance. They address any issues promptly. This ensures the longevity and performance of the Hotel Project Furniture. This comprehensive support minimizes disruptions. It also maximizes the value of the investment.

Navigating the OEM/ODM Process for Hotel Project Furniture

Initial Consultation and Requirements Definition

The OEM/ODM process for Hotel Project Furniture begins with a crucial initial consultation. This phase defines all project requirements. Manufacturers discuss material choices, including hardwoods, composites, and metals. They consider characteristics like durability, weight, and maintenance. Sustainability practices and finish options, such as oils or lacquers, are also important. Clients present design ideas, lifestyle needs, and aesthetic preferences. The manufacturer offers suggestions, sketches, CAD models, and 3D renderings to refine the design. Project timelines are established, covering design, production, and potential delays. Cost estimations address budget constraints, material costs, and design complexity. They also consider delivery, installation, and long-term care. It is essential to specify the intended use of the product, whether for commercial or hospitality settings. This ensures compliance with varying standards and market regulations.

Design, Prototyping, and Sample Approval

After defining requirements, the process moves to design, prototyping, and sample approval. The first week involves placing a detailed order with complete specifications. A project manager is assigned. The manufacturer reviews all details, from dimensions to finish selections. Engineering then begins developing technical drawings. By the second week, these technical drawings are sent to the customer for review. This allows verification of measurements, material selections, and design details. The third week is crucial for customer feedback. Clients provide edits, approvals, or questions after reviewing the drawings. Prompt and thorough feedback is essential. It prevents delays and allows the manufacturer to proceed to the next phase. This stage encompasses sample approval through drawing confirmation.

Production, Quality Inspection, and Certification

Production begins once designs receive approval. Manufacturers implement rigorous quality inspection protocols throughout this stage. They start with initial material inspection. This verifies wood components are free from warping. Upholstery must meet minimum double-rub test standards. Metal components demonstrate corrosion resistance. Manufacturing process oversight ensures precision alignment and uniform dimensions during cutting and assembly. Reinforced stress points and proper adhesive application are critical for joinery. Durability and performance testing includes weight-bearing tests for seating and impact resistance tests. Cycle testing for drawers and hinges also occurs. Safety and compliance standards confirm fire-retardant materials and non-toxic finishes. Rounded edges on guest-contact surfaces and tip-prevention designs for tall case goods are also checked. Aesthetic and finish inspections evaluate color consistency and flawless upholstery. This comprehensive approach ensures high-quality Hotel Project Furniture.

Packaging, Shipping, and Installation Guidance

Effective packaging, reliable shipping, and clear installation guidance are crucial for successful hotel furniture projects. Manufacturers often embrace disassembly, breaking down furniture into smaller components. This minimizes shipping volume and reduces damage risk. Workers organize screws and small parts into labeled ziplock bags. They use bubble wrap, foam padding, and cardboard to protect all parts, especially corners and edges. For bulkier items like sofas, they layer craft paper, bubble wrap, and shrink wrap. Workers pack dismantled parts into sturdy cardboard boxes. They secure these boxes on pallets, ensuring even weight distribution and firm strapping. Clear labeling with handling instructions and sequential numbers is crucial. Manufacturers also take pictures of packed items for insurance purposes.

Essential materials include bubble wrap, corrugated cardboard, foam sheets, and heavy-duty tape. For upholstered items, a plastic wrap base layer protects against stains. Then, foam padding and moving blankets provide further protection. Accurate HS codes prevent customs holds and delays. Manufacturers ensure HS code accuracy to avoid issues. They also include HS notes on packaging labels. For international shipments, custom crates offer enhanced protection.

Planning ahead and partnering with reliable international shipping companies ensures smooth delivery. These companies specialize in furniture and international logistics. Investing in shipping insurance protects the shipment against potential damage. Upon arrival, thorough inspection of furniture for any damage is essential. Documenting issues helps with insurance claims. Clear labeling and organized parts significantly simplify the installation process for Hotel Project Furniture upon arrival.

Maximizing Value from Your Chinese Hotel Project Furniture Partnership

Building Long-Term Collaborative Relationships

Building strong relationships with Chinese manufacturers is crucial for maximizing value. Companies prioritize relationship management. This leads to better support, higher quality products, and increased flexibility. Cultivating relationships (relationships, guanxi) involves investing time in personal relationships and mutual obligations. This builds trust through consistent effort. dignity and reputation (face, mianzi) represents dignity and reputation. Managing it effectively is vital for respect. Avoid actions that might embarrass someone. Demonstrate respect, especially towards leaders. Foster open communication. This helps build strong partnerships. It enables both parties to address challenges collaboratively. Regular communication, even after contracts are signed, strengthens the relationship. Express appreciation for efforts and cooperation.

Understanding Contractual Agreements and IP Protection

Robust contractual agreements are essential. A China manufacturing contract specifies processes, quality standards, and delivery timelines. It also addresses liability. This contract must be in Chinese, under Chinese law, and stamped with an official seal for enforceability. An NDA or NNN agreement protects business information and intellectual property. An NNN (non-compete, non-disclosure, non-circumvention) offers stricter protection. It prevents partners from competing or bypassing the original partner. A product development agreement outlines responsibilities for new product creation. For Hotel Project Furniture, register intellectual property (IP) early in China. China operates on a ‘first-to-file‘ system. Consider a modular manufacturing approach. This uses multiple suppliers for different production stages. This prevents any single manufacturer from accessing complete product designs.

Leveraging Technology for Seamless Collaboration

Technology significantly enhances collaboration with overseas suppliers. Messaging applications like Slack and Microsoft Teams centralize communication. They offer secure, searchable environments for instant updates. Project management tools such as Trello organize tasks visually. They allow users to track progress and assign tasks. This ensures clear visibility for all team members. Sales enablement tools like Showpad optimize content sharing. They help share product information and marketing materials with overseas partners. DealHub streamlines the sales process. It automates quote generation and contract creation. This simplifies quoting and contracting for custom manufacturing. These digital tools ensure efficient information flow and project progression.

Continuous Improvement and Feedback Mechanisms

Successful partnerships with Chinese manufacturers thrive on continuous improvement and robust feedback mechanisms. Manufacturers and clients establish regular, constructive feedback loops. These include partner satisfaction surveys, post-project debriefs, and open forums for idea exchange. This systematic approach ensures ongoing refinement of processes and products.

Rigorous quality control across all partners is essential. Manufacturers implement mutually agreed quality standards. They conduct joint supplier audits. They also transparently share inspection data. This drives continuous improvement in product quality. Furthermore, they prioritize quality assurance and consistency. They establish clear specifications. They conduct regular quality audits. They integrate customer feedback to continuously improve products based on end-user insights.

Leveraging collaborative data and analytics significantly enhances efficiency. Partners share sales data, inventory levels, and customer insights. They utilize tools for partner feedback and operational metrics. This enables data-driven demand forecasting. Technology also plays a crucial role in seamless collaboration. Manufacturers utilize modern tools like supply chain visibility platforms, collaborative design software, and data-sharing dashboards. These platforms enhance transparency, efficiency, and joint innovation.

Facilitating mutual training and knowledge sharing empowers innovation. It enhances capabilities through product education and workshops on industry trends. Collaborative research and development also contribute to this. Manufacturers maintain agility and embrace continuous innovation. They adapt to industry changes through pilot testing new methods and regular performance reviews. They also foster an open innovation culture. This proactive approach ensures the partnership remains dynamic and responsive to market demands.

Chinese custom furniture manufacturers offer significant advantages for hotel projects through their OEM/ODM capabilities. They provide full-category furniture production from a single partner, ensuring design consistency and simplified project management. These manufacturers also offer tailored solutions for various hotel positioning strategies. Selecting the right partner involves careful consideration of their expertise, quality, and support services. Hotels must prioritize quality and durability, customization options, and compliance with certifications like ISO9001 and FSC. Engaging with these manufacturers can lead to high-quality, cost-effective, and uniquely designed Hotel Project Furniture solutions. They offer extensive customization, top-notch craftsmanship, and integrate smart features, enhancing guest experiences.

FAQ

What advantages do Chinese manufacturers offer for hotel furniture OEM/ODM?

Chinese manufacturers provide cost-effectiveness and scalability. They have comprehensive supply chains and advanced technology. Their proven expertise in large-scale production ensures efficiency. They also offer extensive design flexibility and customization for hotel interiors.

How do Chinese manufacturers ensure quality control for hotel furniture?

Manufacturers implement stringent quality checks at every production stage. They inspect raw materials and conduct in-process quality checks. They also perform final product evaluations. Many hold international certifications like ISO 9001.

Can Chinese manufacturers customize furniture to match specific hotel designs?

Yes, they offer extensive customization. Manufacturers provide a wide range of material options, finishes, and dimensions. They translate design concepts into tangible products. They also offer services like 3D rendering and prototyping.

What are the typical lead times for hotel furniture orders from China?

Standard furniture production takes 6–12 weeks. Custom orders require 10–16 weeks. Urgent projects can have aggressive timelines, sometimes 5–8 weeks total. This includes production, quality control, and transport.

Do Chinese manufacturers adhere to sustainability and ethical practices?

Many manufacturers commit to sustainability. They minimize environmental impact and ensure fair labor conditions. Certifications like ISO 14001, FSC, and OEKO-TEX Standard 100 demonstrate these commitments. They use responsibly sourced materials.